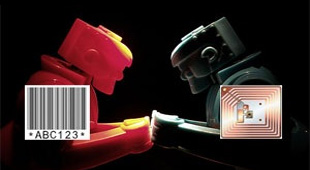

This year marks the 20th anniversary of the most important year in the history of the radio frequency identification (RFID) market.

Gilmore Says.... |

|

| UPS is known of course for its industrial engineering prowess, and smartly applying new technology, so I have no doubt the ROI is there. |

|

What do you say? |

|

| Click here to send us your comments |

| |

|

|

|

Why do I say this? It was in 2003 – also the founding year of SCDigest – that we had two major events:

• The launch of the EPC standard for RFID tags under the organization that has become GS1.

• The announcement of the (infamous) Walmart RFID tagging “mandate” for pallets and cases, which was very consequential even as it ultimately failed.

Early on, there was excitement in the air, and dozens if not hundreds of hardware, software, consulting and other types of companies enjoying dreams of windfall profits to make this happen at Walmart and its many thousands of vendors, and then virtually with all the rest of the retail and consumer goods companies.

But as I will write more about later this year, from the start there were troubles, as the Walmart program for a variety of reasons couldn’t gain traction. That in part led to numerous predictions relative to “tipping points” for RFID.

That term was bandied about quite a bit, mostly by technology companies and consultants, and applied to several scenarios: one was a general tipping point, when RFID would gain some real market mass and become mainstream.

There were also predictions for tipping points where it would make financial sense for consumer goods vendors to go ahead and tag all their products even if a lot of retailers had not yet required tagging, with an add-on notion that as a result such vendors could use the technology for their own distribution benefits as well.

Just one problem: the tipping points were never reached.

Now RFID is again to a degree in vogue, with Macy’s, Target and more recently Walmart back with tagging mandates at the item level, for all three driven by ecommerce and the need for highly accurate inventory levels in store to support BOPIS and store fulfillment of on-line orders.

But somewhat under the radar, I think we may have reached a true tipping point and it is this: UPS has determined automated reading of parcels being placed into trucks with RFID is more cost effective than bar code scanning.

It is rather strange actually that 20 years into the modern RFID era, and that basic question remains largely unanswered. At least, it appears, until now.

Here is the story: as part of its recent Q1 earnings call, UPS said plans to deploy its “smart package” initiative across the rest of its US delivery network this year after its initial success at select facilities in 2022, according CEO Carol Tomé.

The program involves placing RFID tags on parcels and wearable RFID reader devices on employees to eliminate manual scans, reduce misloads and speed movement in the delivery giant’s sorting hubs.

About 100 UPS facilities are currently using the RFID system. UPS said it plans to invest $140 million in the initiative in 2023 as it implements the technology at its 940 remaining US buildings, Tomé added.

CFO Brian Newman said UPS expects to reduce the rate of misloading parcels on to the wrong truck from one in 400 to one in 800 and perhaps even better than that. Misloads are now just one in 1,000 at 50 of the buildings using the RFID system.

And here is the key paragraph: when the program was first announced, UPS said that the use of RFID tags and wearable reader would eliminate 20 million manual bar code scans daily for the employees loading parcels onto trucks. And here is the key paragraph: when the program was first announced, UPS said that the use of RFID tags and wearable reader would eliminate 20 million manual bar code scans daily for the employees loading parcels onto trucks.

UPS is known of course for its industrial engineering prowess, and smartly applying new technology, so I have no doubt the ROI is there.

Now I acknowledge that UPS is handling humongous parcel volumes, and no doubt the ROI calculation would change at more normal distribution operations.

But after much study analysis, testing and real-world results, UPS has decided that a massive initial investment and spending an extra five cents or so per parcel to embed an RFID chip in a label is worth it to eliminate manual bar code scans.

Does this signal the death of the bar code in distribution? Of course not, and any changes will take years to play out.

But UPS is saying RFID is the way to go versus manual scanning. Perhaps we’ll look at this as a true tipping point soon enough.

What is your reaction to these thoughts on UPS as RFID tipping? What would you add? Let us know your thought at the Feedback section below.

Your Comments/Feedback

|

|

Shawn

Supervisor, UPS |

Posted on: Mar, 14 2023 |

|

| Who is the main supplier of RFID tags? Thanks, and great article. |

|

|