Holste Says... |

|

| The theoretical design day approach is actually a compromise between planning for peak or average periods which are both wrong most of the time. Using this approach, system capacity and staffing levels can be scaled up or down to match daily volume fluctuations. |

|

What do you say? |

|

| Click here to send us your comments |

|

|

|

As was previously suggested (see – “DC Capacity Planning”), an alternative approach is to establish criteria for a theoretical “design day” based on an average day during a peak order processing period (week/month in a better than average sales year) plus a growth factor bump-up. The theoretical design day approach is actually a compromise between planning for peak or average periods which are both wrong most of the time. Using this approach, system capacity and staffing levels can be scaled up or down to match daily volume fluctuations.

While staffing levels are relatively easy to adjust, system operations may be less flexible. For example, take into consideration the following suggestions:

- Be cautious of highly automated processes whose efficiency depends on running at full speed. They may not be so efficient or cost effective when volumes are low, and you still have the capital investment to amortize.

- In a mechanized or semi-automated system, along with adequate buffering, provide a path for continuous flow (re-circulation). This will reduce backups and premature system shutdowns.

- Create a mini-DC operation that includes an independent line of flow (like a “slapper” line) for orders and/or customers that have common characteristics. These might include a small sub-set of specific product lines; single lines or single units; the same value added shipping package and/or compliance labeling requirements; or the same carrier. Also, this mini-DC operation may feature workstations for picking and packing as a single-step process.

- Design workstations that have the capability to perform a variety of tasks and locate them so that they are easily accessed from different points in the primary line of flow. These might be configured to support several activities. And cross-train employees so that as the mix of work requirements change, they can be quickly re-deployed.

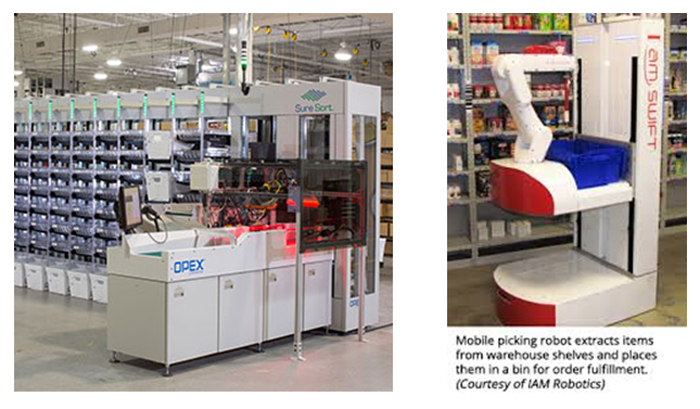

If the volumes of ecommerce orders are beginning to clog-up the primary order picking system consider a separate standalone system such as now being provided by OPEX “Sure Sort” www.opex.com and by I Am Robotics www.iamrobotics.com (see pictures below) as well as other vendors that we have recently reported on.

Final Thoughts

No doubt managing volume fluctuation efficiently is a major challenge. But, you don't have to be victimized by it. By knowing the capacity of each order fulfillment system adjustments can be made so that peaks and valleys can be smoothed-out and operating efficiency maintained.

Any reaction to this Expert Insight column? Send below.

Your Comments/Feedback

|

|

Tom Galluzzo

CEO, IAM Robotics |

Posted on: Jun, 16 2017 |

|

Thanks for including us in your column! Great points.

|

|

|