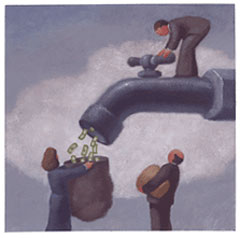

Every year, retailers spend hundreds of millions of dollars to create the “perfect” merchandising plan. Industry demographics are measured and focus groups created in an attempt to define the desired customer. Once the perfect customer and corresponding products are identified, sophisticated forecasting, planning and allocation systems are utilized to construct complex merchandise plans to achieve specific margin objectives.

Unfortunately the results, particularly during promotional or seasonal events, often become missed margin opportunities combined with damage to the retailer's valuable brand because of out-of-stocks (OOS) at the shelf - and now increasingly on-line as well.

While in-store execution issues often lead to OOS, the culprit is just as often suve Bipply chain performance, and that is especially true for on-line out-of-stocks. In truth, the retailer's margin was in jeopardy from the beginning due to unforeseen but predictable supply chain risk factors.

Compliance Networks Says... |

|

| A shorter and/or more predictable purchase order lifecycle is clearly more responsive to demand signals, less prone to out of stocks and requires less working capital to fund. |

|

|

|

It is also important to remember that like products, margin has a shelf life. In the past, the consumer was often patient if a product was not on the shelf, mainly due in part to the fact their options were limited. Those days are of course long gone in the face of hyper-retail competition and the products a consumer wants always being a just a click away.

Five Critical Steps Supply Chain Steps to Drive Better Merchandise Plan Execution

Where does the supply chain executive start in their quest to influence margin performance? While opinions will vary where the best place to start is, most will agree the desired outcome is a more predictable and consistent supply chain. In the presence of variability, there will be high safety stocks to mitigate lost sales from OOS. By eliminating vendor-induced variability and providing merchant teams with actual vendor performance related information, retailers can drive down their overall safety stock and improve profitability.

The following are five steps supply chain executives can take to improve merchandise plan execution:

Step One - Focus on On-time Deliveries and Fill Rate (increase sales): The velocity and cadence of promotional events in the retail industry is greater than ever before. Ensuring orders are complete and on-time are critical to most merchants and are fundamental in reducing margin risk - and smart vendor compliance programs have a proven ability to do just that.

Visit the Retail Vendor Performance Management home page to learn more

and subscribe to the monthly newsletter.

Step Two - Monitor and Reduce the Purchase Order Lifecycle (reduce supply chain days): Retailers should continuously monitor the purchase order lifecycle for supply chain improvement opportunities. A shorter and/or more predictable purchase order lifecycle is clearly more responsive to demand signals, less prone to out of stocks and requires less working capital to fund. Vendor compliance tools can provide this visibility and analytics. Step Two - Monitor and Reduce the Purchase Order Lifecycle (reduce supply chain days): Retailers should continuously monitor the purchase order lifecycle for supply chain improvement opportunities. A shorter and/or more predictable purchase order lifecycle is clearly more responsive to demand signals, less prone to out of stocks and requires less working capital to fund. Vendor compliance tools can provide this visibility and analytics.

Step Three - Monitor ASN Accuracy Religiously: Poor ASN accuracy can doom inventory integrity, leading to poor merchandise plan execution. While it's important to audit vendors for accuracy, it is also important to focus valuable audit resources on the lower performing vendors versus the higher performing vendors. A vendor compliance tool can drive this audit segmentation.

Step Four - Monitor Transportation Performance: Ensure vendors are adhering to the routing guide for transportation requirements. The selection of a wrong mode or carrier can result in additional supply chain days, while multiple shipments during the same week can accelerate transportation expenses.

Step Five - Over Communicate with Your Vendor Trading Partners: Provide vendors 24/7 access to key performance data. Immediately alert vendors to past supply chain failures, or if possible, alert them to upcoming execution opportunities. Over communicating performance data to key trading partners will result in visibility for all parties involved.

Summary

The value of merchandise plan execution is critical to any retailer's margin objectives. By systematically identifying and eliminating supply chain performance related issues, retailers can mitigate those events that put margin at risk. In an economy where working capital still remains constrained, the supply chain professionals who can run a predictable and consistent supply chain, influence margin performance, and increase operating cash flow will be quite valuable indeed.

Any comments on this article? Please send below.

Your Comments/Feedback

|