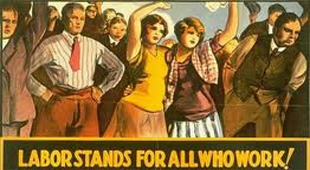

Monday of course marks the annual Labor Day holiday both here and in Canada. Starting in 2011, I decided to do a column on the state of the labor supply chain in conjunction with this event. It was popular enough that I have continued on each year since. It's a lot of work, but well worth it.

It's clear the labor movement in the US continues to weaken. The percent of total US workers that were union members was down in 2016 to 10.7% from 11.1% in 2015, according to the US Bureau of Labor Statistics. Unionization in the private sector was also down, to just 6.4% in 2016, from 6.7% in 2015.

Conversely, union membership in the public sector was 34.4% last year, although for reasons not clear that was also down from a rate of 35.2% in 2015.

Gilmore Says.... |

|

| In early 2017, Missouri voted to become the 28th right-to-work state, joining Kentucky earlier in the year and Michigan, Wisconsin and Indiana in prior years. |

|

What do you say? |

|

| Click here to send us your comments |

| |

|

|

|

All this of course continues the powerful long-term trend of a steady decline since the Labor Department started reporting on it in 1983, when overall unionization was at 20.1% and at 16.8% in the private sector. Those numbers themselves were well down from previous decades before this metric was tracked by the government.

I will note part of that decline in private sector unionization rates is due to the loss of some 7 million US manufacturing jobs since 1983, as manufacturing is clearly more organized than the service sector, but that is far from the only factor. Unions have clearly lost appeal to many, especially in the South, where many new manufacturing factories have been headed for some two decades.

Together, there were 14.5 million private and public sector employees in a union in 2016, down from 14.8 million 2015, and well down from 17.7 million in 1983 when the total US labor force was much smaller.

There are also huge differences between states. Five states had union membership rates below 5% in 2016: South Carolina (1.6%), North Carolina (3.0%), Arkansas (3.9%) Georgia (3.9%), and Texas (4.0%). Conversely, just one state had union membership rates over 20 percent in 2016: New York at 23.6%. Other high union states are Hawaii (19.9%), Alaska (18.5%), Connecticut (17.5%) and Washington (17.4%).

All told, union membership rates decreased over the year in 31 states and the District of Columbia, increased in 16 states, and were unchanged in 3 states.

The number of US manufacturing workers that are union members fell in 2016 to just 8.8% from 9.4% in 2015 - that is quite a drop. Those numbers are a bit lower than the percent of workers covered by union contracts, such as those that opt out in right-to-work states, with coverage of 9.6% last year and 10.0% in 2015.

Ponder that - less than one in 11 US manufacturing workers are unionized today, versus 17.5% in 1994. According to unionstats.com, 38% of private sector manufacturing workers were in unions as recently as 1973.

Don't think this downward union trend is only a US phenomenon. Unionization rates in labor-loving Sweden, for example, have fallen from about 90% in the mid-1990s to around 70% today. Many other countries mirror US unionization rates more closely. Unionization in France - generally considered very supportive of labor - almost exactly follow the US patterns, and are actually just below the US in the percent of all workers unionized. Union membership is higher in the UK, at 23.5%, but that's down from more like 40% in the mid-1990s. The drop in the UK's total number of union members in 2016 was 4.3%, the largest annual drop recorded since the measure began in 1995.

In July, there were about 8.72 million non-supervisory manufacturing workers in the US, up solidly from 8.6 million a year ago. That is also up from the bottom of the recession, when we fell to about 8 million shop floor workers, meaning we've added about 720,000 manufacturing jobs since then. But in 2004, there were just over 10 million factory floor workers - we're down almost 1.3 million positions from that level, and much more from the 1990s.

That obviously puts general downward pressure on wages, as the demand for workers is simply much lower than the supply, though the lack of wage growth isn't nearly as bad as I would have guessed, based on all the media reports.

According to the BLS, the average hourly wage (I believe including benefits) for shop floor manufacturing workers was about $20.94 in July, up from $20.47 in 2016, or about 2.2% growth year over year - not too bad.

That's also up from the $17.29 or so per hour in July 2007, or a rise of 23% over 10 years. That's a cumulative growth rate of 1.93%. So wages have risen modestly, about equal with inflation, and thus not enough to improve a worker's lifestyle, especially while healthcare costs take more and more of the paycheck.

Meanwhile, there has been very steady growth in non-supervisory warehouse jobs, though they represent just a tiny fraction of manufacturing positions. There are now about 837,000 warehouse workers in the US, up sharply from some 792,000 in July 2016, an increase of 5.6%. The number is substantially higher than the 574,000 warehouse in 2007, a rise of 38% over 10 years - but even with that growth they only represent about 9.6% of manufacturing floor jobs. That surprises me, actually, though that percentage continues to slowly tick up. (I'll note some jobs at plant warehouses may be counted as manufacturing positions.)

In terms of wages, average non-supervisory pay for warehouse workers was $16.95 in June, up an incredibly sharp 11.2% year over year. That's also about 19% less than average manufacturing rate - but the gap is shrinking. It was 23% last year. Pay for warehouse workers was at $15.23 in June 2007, meaning DC wages have risen only 11.2% over the past decade. Given the growth in jobs, that is surprising, though the recent trend is obviously for faster wage growth as distributors strain to fill positions. We've heard of $18+ per hour in some tight markets.

And that before Amazon's move to hire an amazing 50,000 fulfillment center workers by year's end.

OK, those are some of the key data points.

Now let's look at some of the important events and trends relative to labor over the past year.

Once again, unions lost in the two most high profile unionization efforts - both in the South.

The first was at the Boeing factory built in 2014 with some controversy (for moving the production of a new aircraft from Seattle). This was an interesting situation, as then governor Nicky Haley basically said "Unions leave South Carolina, we don't want you hear," in a sentiment that for example would likely not be offered in New Jersey.

But the union came any way, and eventually organized a vote for representation in February. It wasn't even close. Out of the approximately 3,000 workers eligible to vote, 2,097 said no to joining the International Association of Machinists. That was an amazing 74% of the 2,828 votes cast. You have to wonder why the union pressed ahead for the vote.

More recently, the United Auto Workers continued its quixotic quest to unionize even just one of the foreign auto assembly plants in the South, after failing several times before, most notably at a Volkswagen plant in Tennessee in 2014, when the union went down in flames despite management seeming to actually support unionization.

This year it was a Nissan plant in Mississippi, which again soundly defeated the unionization proposal, with more than 63% of Nissan plant workers saying No.

"It certainly is a huge setback. It's a challenge. It shows how incredibly hard it is to organize both in the South and at international firms," Kristin Dziczek, director of the labor and industry group at the Center for Automotive Research in Ann Arbor, said at the time.

Also a setback for labor was another increase this year in the number of so-called right-to-work states, in which employees can't be compelled to join unions. Once mostly found only in Southern and some Western states, recently states in the Midwest have jumped on the bandwagon despite furious opposition from labor. Also a setback for labor was another increase this year in the number of so-called right-to-work states, in which employees can't be compelled to join unions. Once mostly found only in Southern and some Western states, recently states in the Midwest have jumped on the bandwagon despite furious opposition from labor.

In early 2017, Missouri voted to become the 28th right-to-work state, joining Kentucky earlier in the year and Michigan, Wisconsin and Indiana in prior years. There is also right-to-work activity in the Ohio and New Hampshire legislatures.

The $15 minimum wage movement went mostly nowhere in the past year, including one negative analysis of the impact of Seattle's mandate on jobs.

So it wasn't a good year for labor, but there we a couple of bright spots.

The UAW can be said to have mostly won with its new contract after a bitter 32-day strike at a Kohler factory in Wisconsin in December. The union didn't get everything it wanted, but did achieve a boost in wages, minimized the employee impact of rising health care costs, and improved pension benefits -better than many contracts outside the Longshoremen these days.

There were some wins here and there in the never ending debate on whether contract drivers really should be classified as employees, including a Federal court judge in North Carolina granting permission in July to a group of Uber drivers challenging the company's classification structure to band together in a nationwide legal action. Watch out trucking firms.

After a powerful article in USA Today this summer highlighting what can accurately be termed abuse of some contract drivers by trucking companies, especially for drayage service in California, some major shippers (e.g., Costco) are looking at ending relationships with some of these carriers.

There's a lot more, but I am well out of space. The issue for labor is not yet "here come the robots," but will be soon.

Any reaction to our summary of the labor supply chain 2017? Let us know your thoughts at the Feedback section below.

Your Comments/Feedback

|