Over the last decade, numerous articles have been published on the benefits of automation in the DC. While the adoption rate is growing among high volume shippers, most small to medium operations are just beginning to consider how an investment in automation may be beneficial. Many of these business managers are more likely to adopt a standalone or focused automation strategy preferring to avoid, or at least delay, the larger capital expense and disruption associated with a total system approach.

Holste Says... |

|

| As operational complexity increases, equipment and systems that are designed to run with little or no manual intervention are essential for business growth and profitability. |

|

What do you say? |

|

| Click here to send us your comments |

|

|

|

It appears that deploying smart, efficient, and cost effective automation will continue to play an important role in improving DC performance going forward. Modularity, adaptability, reliability, and speed are the keys to adoption. As operational complexity increases, equipment and systems that are designed to run with little or no manual intervention are essential for business growth and profitability. However, DC automation does not have to be an all or nothing proposition. Within the traditional DC model there are many practical applications for automated solutions.

The following are a few examples of the most popular standalone solutions:

- Automated Print & Apply Labeling

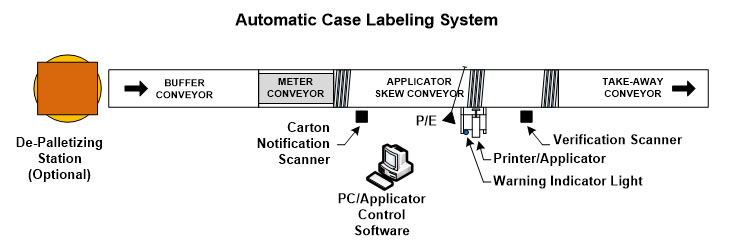

In a manual receiving and/or picking operation getting the right customer bar code label onto the proper case can be a time consuming headache. In the early 1990s equipment providers developed various automated methods for systematically printing and applying customer specific bar coded shipping compliance labels (GS1-128 formerly called the USS-128) to the side, top, or end of case. The sketch below shows a typical standalone equipment arrangement.

It’s interesting to note that stand alone labeling systems similar to the above arrangement are available on mobile base frames so that they can serve where needed on the receiving or shipping dock.

We generally don’t think of a pick cart as a piece of automation but, when equipped with GPS tracking, and voice commands or pick-to-light devices to direct and confirm actions, all driven by a robust order fulfillment software package, the result is computer directed (automated) task management.

Picking carts of all types have been in use in DCs for as long as there has been DCs. However, time has not stood still for the ever popular pick cart. A few years ago GNC used in-house expertise to develop their own “automated” piece picking carts. Several years ago GNC took a DIY approach: the company looked at pick-to-light and voice technology along with other approaches to semi-automate their piece picking process for its three US distribution centers, but in the end, went with a unique pick cart system it developed in-house that enables very high levels of throughput and accuracy. Picking carts of all types have been in use in DCs for as long as there has been DCs. However, time has not stood still for the ever popular pick cart. A few years ago GNC used in-house expertise to develop their own “automated” piece picking carts. Several years ago GNC took a DIY approach: the company looked at pick-to-light and voice technology along with other approaches to semi-automate their piece picking process for its three US distribution centers, but in the end, went with a unique pick cart system it developed in-house that enables very high levels of throughput and accuracy.

- Automated Weigh-In-Motion, Cubing and Manifesting

There are several equipment providers that offer pre engineered weigh-in-motion shipping manifest systems that can process up to 50 parcels per minute, depending upon carton size. These systems can have unattended conveyor lines with automated cubing, weighing, rate shopping, routing, labeling, manifesting, and shipping sortation. The systems are scalable to meet the needs of a wide range of operations. There are several equipment providers that offer pre engineered weigh-in-motion shipping manifest systems that can process up to 50 parcels per minute, depending upon carton size. These systems can have unattended conveyor lines with automated cubing, weighing, rate shopping, routing, labeling, manifesting, and shipping sortation. The systems are scalable to meet the needs of a wide range of operations.

With this level of automation, once the system knows the cube and weight of each item on a customer’s order, the data then can be sent to a real-time host system or to a WMS to automate the calculations and determine the most economical shipping case size based on DIM weight pricing. An added benefit will be realized in fewer back-charged bills from carriers.

Other popular examples of where automation can be adopted include: A-frame picking machines, Horizontal Carousels, and Vertical Lift Modules. Automated piece picking solutions utilizing a new generation of autonomist robots especially designed for the DC environment are just beginning to emerge.

Of course the cost of deploying an automated or semi-automated solution depends on many factors. However, industry reports indicate that these types of investments pay for themselves in months by reducing labor and eliminating inaccuracies inherent in manual processes. Applied properly they can become building blocks leading to a more responsive and productive operation.

Final Thoughts

Driven by multi-channel marketing and customer demand for higher levels of service the justification for automated solutions in the DC has more to do with planning, control, and processing strategy than it does with the physical movement of goods.

Any reaction to this Expert Insight column? Send below.

Your Comments/Feedback

|

|

Rajesh

Marketing Manager, Falcon Autotech |

Posted on: Nov, 22 2016 |

|

Falcon Autotech has developed its in-house Pick to Light and Put to Light Technology platform that is widely deployed in various applications such as:

1. Packet Sortation

2. Online Multi-Line Order Consolidation

3. Picking Automation/ Kitting

4. Store Order Fulfilment

|

|

|