From SCDigest's On-Target E-Magazine

- Sept. 7, 2015 -

Supply Chain News: Explaining the Difference between Task Management and Task Interleaving in WMS

Use of Task Interleaving Often Requires Rethinking DC Flows

SCDigest Editorial Staff

The market for Warehouse Management Systems (WMS) continues to be pretty strong, driven by requirements for omnichannel fuflillment, systems that support DC automation, rising volumes since the end of the recession in 2009 and more.

SCDigest Says: |

|

| An intelligent WMS can understand the total work pool that is available on the floor, and look for a complementary task that can be linked to the original task assigned to the operator.

|

|

What Do You Say?

|

|

|

|

Task management - or the delivery of work to DC associates in the most optimal way, generally using radio frequency terminals or Voice devices - is one of the foundational capabilities of any WMS, and needs to be well vetted by companies considering a new DC system.

Many WMS vendors, in turn, often push the concept of "task interleaving," one potential aspect of tsk management that involves combining tasks for one associate, generally one on a fork truck, to improve productivity by reducing "deadheading," or travelling empty.

Every few years, SCDigest takes a look at these two important concepts.

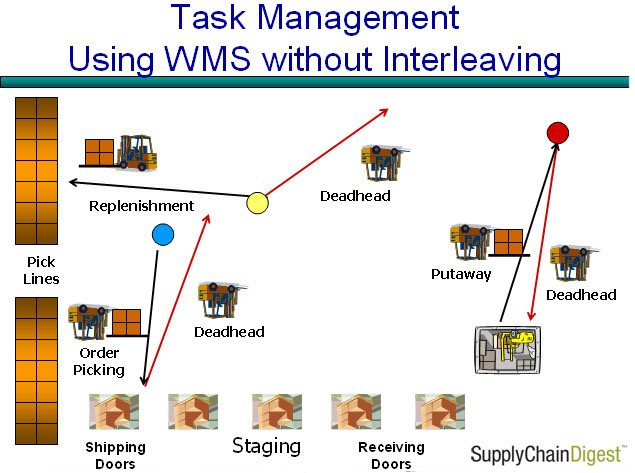

The task engine in a WMS is configured to understand all the possible types of work in a DC, especially for mobile workers. That work includes such activities as putaway, order picking, replenishment, truckloading, and much more (see graphic nearby). WMS systems will usually offer options about which types of tasks the system should assign versus which ones operators will self-assign (or receive through a supervisor) and report via scanning or other means what work they have performed.

The task management engine really can be considered the brains of the WMS, understanding what work needs to be accomplished, and assigning the work from its queue to specific workers, typically via wireless RF terminals or voice commands. In higher-end WMS systems, those tasks are assigned to individuals based on the so-called "3 Ps":

Permission: Is the operator permitted to do a specific task (training, certification, on the right type of equipment, etc.)?

Proximity: Is it efficient for the operator to do a task based on where he or she is in the DC right now compared to others?

Priority: How important is this task (for example, is it a "hot" replenishment")?

Each WMS will have its own specific algorithms for how these factors are combined to assign tasks to workers. Generally, the task management configuration process will offer flexibility in how these rules are established. The system should also allow the generated task assignments to be "overruled" in real-time by floor managers if needed, though the ease of doing this will also vary from system to system.

An early problem with WMS task management systems was that in a busy distribution center, low priority tasks sometimes never were sent to the floor, and they were constantly trumped by new higher priority tasks. The vendors solved this by putting a configurable timer on each task (say 10 or 20 minutes), after which the priority would be bumped up one level (say from a 5 to a 4).

The task management engines are increasing "event driven." So, for example, the event of a very narrow aisle truck dropping a pallet it picked up at the end of an aisle triggers a task for a traditional lift truck to come movit to staging or other location.

Task Interleaving Goes a Step Further

"Task interleaving" takes the power of the WMS task management engine to a new level by combining tasks for operators in a distribution center to increase productivity and reduce equipment "deadheading." Interleaving isn't for every DC, but can drive big productivity gains for those that can make it work.

While putaway, picking, etc., are the most obvious and generally most critical tasks to consider for interleaving, the maximum value will be achieved if the task engine is looking across most or all types of work in the DC in its pool of work to be assigned.

In DCs without interleaving, at any given time workers are typically focusing only on single tasks, such as putaway, which would mean driving back empty to receiving after each piece of work.

As shown in the illustrations nearby, with task interleaving different types of tasks can be assigned to a given operator, such as giving an operator a full pallet pick for a replenishment task in the case pick area after he or she has just completed a full pallet putaway.

The tasks assigned to workers are still determined based on the three P's of permission, priority and proximity, but now with the pool of available assignments across task types, not for just a specific type of task.

(Distribution/Materials Handling Story Continues Below

)

|