From SCDigest's On-Target E-Magazine

June 15 , 2011

Supply Chain News: Is it Possible to Determine the Right amount of Supply Chain "Redundancy?"

Lurking Concerns Supply Chains have become too Lean; Can Risk Potential be Quantified?

SCDigest Editorial Staff

In a recent commentary, IDC Manufacturing Insights analyst Simon Ellis asked a simple question - is it really possible to determine the optimum level of redundancy or "slack" in a supply chain?

SCDigest Says: |

|

Apple, for example, saw wait times for customers trying to order an iPad 2 rise form 3-5 days to 4-5 weeks due to component supply problems from Japanese vendors.

|

|

What Do You Say?

|

|

|

|

There have been many articles in recent years noting that the sometimes extreme focus on Lean has left many supply chains "brittle," subject to big hits in the face of a disruption. Those views came to the forefront again recently after the earthquake/tsunami in Japan, which caused supply chain disruptions in a number of industry sectors.

Apple, for example, saw wait times for customers trying to order an iPad 2 rise form 3-5 days to 4-5 weeks due to component supply problems from Japanese vendors.

In his research note, Ellis cites recent research coming out of the University of Toledo and McGill University in Canada that showed that resource efficiency, with a level of redundancy built in, drives higher financial returns than a more hard core Lean strategy — based on the financial performance of all publicly traded U.S. firms from 1991 to 2006. (We will look at this specific research in more detail soon.)

"While this finding might initially be viewed as somewhat self-evident, the dilemma goes right to the heart of supply chain risk management. Do I build in redundancy, "slack" as McGill called it, with its accompanying short-term costs, or does the inherent chase for cost efficiency cause me to strive for the highest possible utilization levels and "hope" that nothing major goes wrong?" Ellis ponders. "It is, essentially, the same debate that companies have been having more broadly about supply chain risk and the appropriate levels of mitigation."

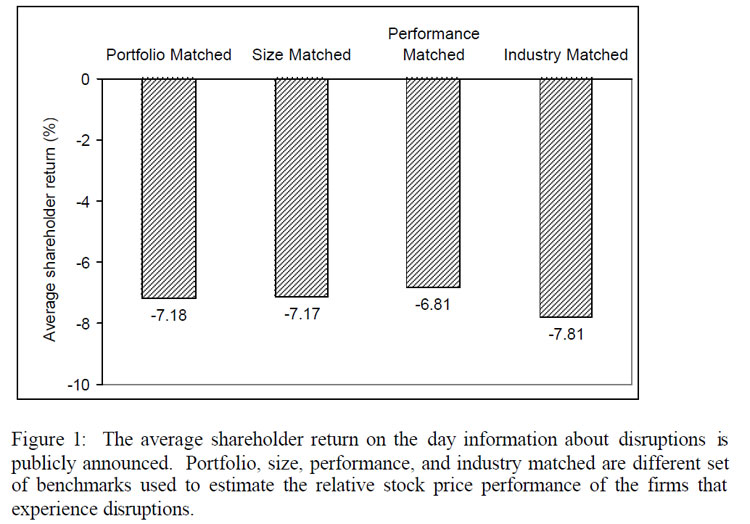

Research out of Georgia Tech has shown the powerful negative impact a supply chain disruption can have on a company's share price - and impact that usually lasts well after the original disruption has been solved.

As shown in the chart below from that research, on the day a company announced a supply chain disruption, its stock price falls about 7% versus peer companies by industry, size, etc.

First Day Impact on Stock Price of SCM Disruption Announcement

Source: Kevin Hendricks and Vinod R. Singhal

(Supply Chain Trends Story Continued Below)

|