Holste Says: |

|

| Sometimes finding additional "hidden" storage space requires departing slightly from conventional thinking. |

|

What Do You Say?

|

|

|

|

Previous Columns by

Cliff Holste |

|

|

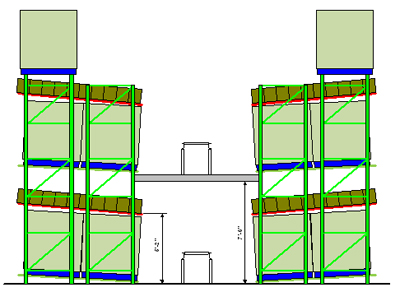

Most DC managers are perpetually searching their facilities for usable and accessible storage space. In especially high demand is active or on-line stock picking locations. For those DCs equipped with multilevel picking modules there is often unused space available within the module as shown in the following two examples:

Example #1 - Adding Case Flow Lanes above Pallet Flow Positions

While pick-to-belt modules are efficient for order picking, they are not all that great when it comes to space utilization.

The adjacent sketch shows a typical two level high double-deep pallet flow pick module. The vertical clearance for the second level mezzanine is shown at 7½ feet above the floor, which is about the minimum requirement for such applications in order to satisfy code. The adjacent sketch shows a typical two level high double-deep pallet flow pick module. The vertical clearance for the second level mezzanine is shown at 7½ feet above the floor, which is about the minimum requirement for such applications in order to satisfy code.

Unfortunately, this arrangement can leave a large void above the top of the pallet loads. Often, this dead space can be put to good use by installing a shelf of carton flow lanes into the pallet flow rack. This can be easily accomplished by utilizing standard components readily available from rack suppliers. Now, this previously dead space becomes a productive on-line picking location for slotting additional slow to medium velocity SKUs.

|