For the last several years, SCDigest has partnered with Gartner on a survey of our readers on a variety of supply chain issues and trends. It’s always an interesting piece of work, and I think especially so this year, which is sort of a “tweener,” with signs of economic recovery but everyone still a bit nervous just the same.

The research is led by Gartner analysts Dwight Klappich and Chad Eschinger, who now operate under the Supply Chain Leaders/AMR Research arm of Gartner, after Gartner acquired AMR late last year.

The results were published to Gartner clients a few months ago, but we have to wait awhile to share them with general SCDigest readers. A presentation on the study was just delivered by Klappich and Eschinger at AMR Supply Chain Executive Conference a few weeks ago, so we thought now was a good time to provide some of the highlights.

Gilmore Says:

|

|

"The third barrier, internal collaboration and visibility, is one that is obviously directly under a given company’s own control. Why haven’t more companies solved these issues?"

What do you say? |

|

Send us

your Feedback here |

|

First, I was interested in how companies described their own approach to supply chain technology adoption and the role of supply chain in their organizations.

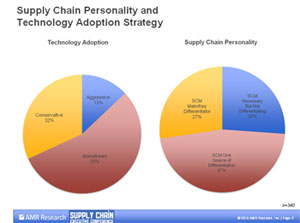

As can be seen below, not surprising the preponderance of companies (55%) describe themselves as “mainstream” in their approach to technology adoption, versus just 13% “aggressive” and 32% “conservative.” That sounds about right to me, though I suspect if an independent observer went in, a decent number of those companies that consider themselves mainstream might be better classified as conservative (to the dismay of supply chain technology vendors).

View Full Sized Image

In another dimension, 27% of respondents said supply chain excellence was a main or key differentiator for their companies; 47% said supply chain was one of several differentiators, while 26% said SCM was a necessary function but not a differentiator to their firms.

Again, this sounds about right to me, though from some work we’ve done here in the past, there can be a disconnect between how important SCM professionals in a company think supply chain is for overall success versus what the CEO or others CXO’s may perceive. The great news is that the recognition of SCM’s role is extraordinarily higher today than it was a decade ago.

In a small but important change in this year’s results, for the first time in the three years of the study, “reducing operating costs” was not the number 1 imperative of supply chain initiatives. While still number 2 (to no one’s surprise), the top spot was taken by “improve efficiency and/or productivity,” which moved up from number 4 in 2009.

While one might argue that cost reduction and productivity increases are the same thing, there is a subtle difference, Klappich points out. He believes that after heavy cut cutting, including plenty of layoffs, during the recession, companies are now looking at how they can participate in the recovery that must eventually come frankly without adding back to the types of headcounts that they had before the recession (which seemed plenty lean to me already in most cases).

So, that is good news for supply chain technology vendors, who surely will hope to help deliver those productivity gains, and indeed spending on supply chain software held up reasonably well even during 2009 and has been strong thus far in 2010. This productivity focus is manifested in part, for example, in the tremendous increase in the number of SKUs each demand planner is now managing at most companies, which has grown several fold over the past 10 years. That is the direct result of more sophisticated technology, which can automate more of the process and let demand planners “manage by exception.”

Interestingly, three years out (2012) the number 1 supply chain driver is predicted to be “supporting company growth.” Will that hold true (growth ranked #4 in this year’s survey)? This result can be looked at in part as a prediction of when we will finally see robust overall economic growth. But something tells me cost cutting may find its way to the top yet again even in 2012, as it usually does.

Top Barriers to Achieving Supply Chain Goals

What did respondents see as the top barriers to achieving their supply chain goals? The top three obstacles cited were as follows, along with the percentage of respondents identifying each barrier (respondents I believe were asked to select their three most important barriers):

- Forecast accuracy/demand variability (59%)

- Supply chain network complexity (42%)

- Lack of internal cross functional collaboration and visibility (39%)

A couple of interesting things to me there. First, as Klappich notes, “Even with the billions of dollars spent on supply chain planning, the same issues linger (i.e., forecast accuracy and demand variability as number one obstacle by long shot to achieving goals.) A common question is: Are all the SCP applications weak?”

No, he says, “These applications continue to improve, but the issue is that the ability of companies to exploit these systems long term is proving difficult.”

Second, the third barrier, internal collaboration and visibility, is one that is obviously directly under a given company’s own control. Why haven’t more companies solved these issues, or made more improvements internally? That’s a fine question we will address on another day.

Perhaps then not surprisingly, “improving planning processes” was cited by respondents as the number 1 supply chain investment priority, with 20% of respondents (one choice only). That was followed by “aligning corporate and supply chain strategies” and “improving supply chain visibility,” both at 11%. Surprising to me was that improving external supply chain collaboration, often cited as the sort of panacea for a variety of supply chain woes, came in very low, cited by just 3% of respondents (though in fairness, it could be that improving collaboration is just not seen as requiring much investment).

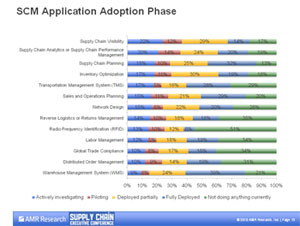

Finally, you might find the following chart interesting, which shows a series of supply chain application areas, and where companies say they stand in terms of adoption. It is a benchmark, really, against which you might compare your own company.

The top application area in terms of full deployment was “warehouse management system,” and even that was fully deployed by only 39% of respondents. That was followed by “supply chain planning” (32%), sales and operations planning (29%), and transportation management systems (28%). However, the chart shows in these and all the categories listed to what degree companies also had partially deployed these apps, were in the process of deploying, etc. 51% of respondents were “not doing anything currently” with RFID.

This chart is a good one.

View Full Sized Image

There’s more, but I am out of space. We will try to cover more later in SCDigest, and may do a webcast on this. I will leave with one more note, and that is the interesting fact that those companies which said that SCM was a key differentiator for them were much more likely to focus on driving growth via the supply chain than other companies, which were more focused on cost reduction. Another provocative point to ponder.

I expect we will do the study starting with a survey again in late 2010 – we encourage you to participate.

Any reaction to this Garter study data? Anything surprise you? What do you see as the largest barriers to achieving supply chain goals? Why isn’t forecast accuracy better? Let us know your thoughts at the Feedback button below.

Web Page/Printable Version of Column

|