From SCDigest's On-Target e-Magazine

Feb. 15 , 2012

Supply Chain News: Is it Time to Make Supplier Risk Management Programs more Real-Time?

International Monetary Fund Builds Database and Analytic Tools to Identify Potential Worrisome Patterns Sooner

SDigest Editorial Staff

Supply chain risk management generally and supplier risk management particularly have been one of the most dominant supply chain trends over the past 3-5 years. Concern about supply chain risk management has grown even more in the past 12 months as a result of the significant hits delivered to hundreds of supply chains from the earthquake/tsunami in Japan in March of 2011, and then mass flooding in Thailand in the second half of the year.

SCDigest Says: |

|

Leong says that on top of the database, the IMF has applied a series of heuristic tools (logical rules) that find patterns among the data and look for specific types of incidents that experience has taught the organization might lead to problems at a supplier.

|

|

What Do You Say?

|

|

|

|

But do companies need to move from the traditional, somewhat backward looking approach to supplier risk profiles to one that is more real time?

That's what Jin Leong, chief procurement officer for the International Monetary Fund in Washington, DC, says he believes.

Writing in a recent edition of ISM's Inside Supply Management magazine, Leong says that "Traditional risk management approaches take a static, often outdated, snapshot of risk. Steps like prequalification, risk classification and periodic maintenance reviews rely predominantly on backward-looking indicators and do not necessarily capture future risks."

Instead, Leong says, "what businesses today need is a risk management program that anticipates risk and potential supply disruptions in advance, so that mitigating actions can be taken before the disruption occurs."

We doubt there would be much disagreement with that. The question, of course, is how do you get there?

Leong says that last year, he and a colleague at the IMF (Caro Cook) developed an approach to risk management that would do just that. They say what makes the approach different is that it enables companies to augment traditional risk indicators like Dun & Bradstreet ratings and historical financials with real-time supplier observations. They say that while often single observations for a given supplier do not indicate risk or financial distress, when those factoids are viewed holistically over a period of time and in combination with other indicators, they allow supply management professionals to get a better sense of a supplier's internal situation.

Building the Database

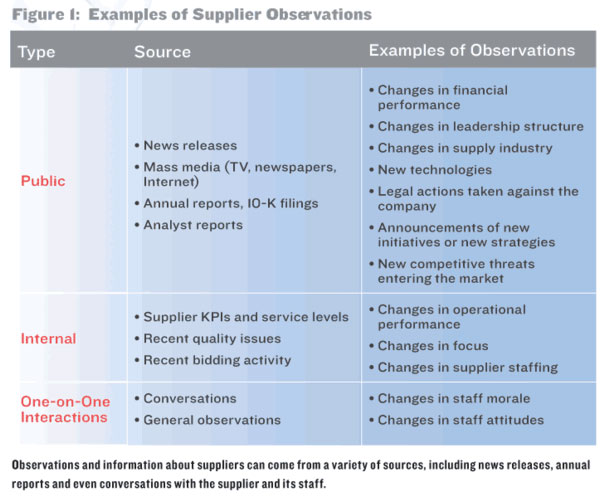

The heart of the program was the construction of a "supplier observation database." This database is primarily populated with information from the organization's supply managers, who are encouraged to enter into the database any real-time observations about suppliers with whom they work. Sources for these observations can include news releases, industry reports, changes in performance or service levels, financial releases, news about competitors, public announcements, leadership changes, and changes in risk ratings, to cite the most common.

As noted above, unless it is a major incident such as a bankruptcy, a given negative observation usually won't mean that much. But when viewed over some longer horizon, like the past quarter or six months, a collection of such observations can provide advanced insight that a given supplier may be having issues that could lead to problems or a true disruption to a company's supply chain.

Leong notes that both positive and negative observations are meant to be entered. They can be characterized by whether they objective (say quarterly earnings report) or subjective (the supplier's CFO had a tough time explaining the company's financial situation.). The sources can be noted as private or public information (see graphic below).

Source: Jin Leong, IMF from Inside Supply Management

The IMF also feeds data from information it receives from the profiles all suppliers are required to submit into the database.

(Sourcing and Procurement Article Continues Below) |