From SCDigest's OnTarget e-Magazine

Jan. 10 , 2011

RFID and AIDC News: US Air Force Tracking Global Assets with Data Matrix 2D Bar Codes, has Labeled its 1 Millionth Item on Way to 2.1 Million

Program went Ahead of Schedule, as 72,000 Assets Labeled and Scanned Each Month

SCDigest Editorial Staff

Several years ago, the US Air Force was charted to track all of its "Class VII" legacy physical global assets - more than 2 million pieces of equipment in the end - using a unique bar code identifier, or what it calls Item Unique Identification (IUID).

SCDigest Says: |

|

| The scope of the effort encompasses 230 locations across the world, and will conclude this March, when approximately 2.1 million assets will have been labeled and tracked.

|

|

What Do You Say?

|

|

|

|

In the fall of 2011, the Air Force celebrated a milestone when the 1 millionth asset was labeled and scanned. The tracking program is managed out of Wright Patterson Air Force base near Dayton, OH.

This identification mandate promotes asset life cycle management and supply chain discipline and is enabling the Air Force to tie asset data across multiple sources to the IUID. The Air Force says this will drive more efficient use of asset data in business processes and increases financial and physical asset accountability. Implementation of IUID will ultimately lead to cost savings through processes automation, improved acquisition, and timely capture of reliable data.

The Class VII assets refer to major end items or pieces of equipment, not sub-components, consumables, or other items that may also be tracked.

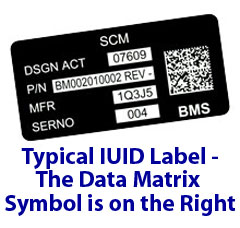

According to a program manager for the project at the Wright Patterson base, the IUID data is encoded into a Data Matrix two-dimensional bar code symbol. The IUID can be of one of two types in terms of data structure.

Type I IUIDs consist of a single Issuing Agency Code (IAC) spelled out in ISO/IEC standard 15419, followed by an Enterprise ID (EID), followed by a unique serial number unique within the EID. CAGE Code is the most popular EID used in Dept. of Defense. So the syntax for Type I UII is IAC+CAGE+S/N.

Type III IUIDs consist of a single Issuing Agency Code (IAC) spelled out in ISO/IEC standard 15419, followed by an Enterprise ID (EID), followed by a part number, followed by a unique serial number unique within the part number. So the syntax for Type I UII is IAC+CAGE+P/N+S/N.

The two types of IUIDs were developed to account for how different industries serialize items. Some industries serialize within their enterprise (Type I) because part numbers can roll as configurations are updated. Other industries never change the part number and therefore use the serialize within part number (Type II).

There number of different label types being used across the globe, but a Wright Pat spokesperson says that "The most common type of label material used is TESA tape. To create the finished label, the outer coating is vaporized by a laser, exposing the white material underneath" to "print" the text information and the bar code, as shown in the graphic nearby. Other types of materials, such as metal labels, may also be used. There number of different label types being used across the globe, but a Wright Pat spokesperson says that "The most common type of label material used is TESA tape. To create the finished label, the outer coating is vaporized by a laser, exposing the white material underneath" to "print" the text information and the bar code, as shown in the graphic nearby. Other types of materials, such as metal labels, may also be used.

The labels are affixed to the assets, then scanned in using mobile readers to the Air Force's Equipment Management System (AFEMS). The assets will be scanned via the inventory module contained in AF's Automated Inventory and Marking Tool (AIMT) application. AIMT will update AFEMS through the Enterprise Data Collection Layer (EDCL) within the application.

The scope of the effort encompasses 230 locations across the world, and will conclude this March, when approximately 2.1 million assets will have been labeled and tracked.

(RFID and AIDC Story Continued Below)

|