|

|

About the Author |

|

Cliff Holste is Supply Chain Digest's Material Handling Editor. With more than 30 years experience in designing and implementing material handling and order picking systems in distribution, Holste has worked with dozens of large and smaller companies to improve distribution performance. |

|

Logistics News

By Cliff Holste

October 22, 2014

|

|

Avoiding Non-Compliant Labeling Issues

Understanding the Effect of Regulatory Standards in a Global Supply Chain

|

|

Holste Says: |

|

| Adhering to regulations that define how products are developed, marketed, shipped, and disposed is essential to avoid fines, retain customers, enter new markets, and in some cases, stay in business. |

|

What Do You Say?

|

|

|

|

Previous Columns by

Cliff Holste |

|

|

There can be no doubt that we are all living in an increasingly regulated world. Companies, especially those doing business through the Global Supply Chain, must pay close attention to the impact of emerging standards and regulations on their operations. Adhering to regulations that define how products are developed, marketed, shipped, and disposed is essential to avoid fines, retain customers, enter new markets, and in some cases, stay in business.

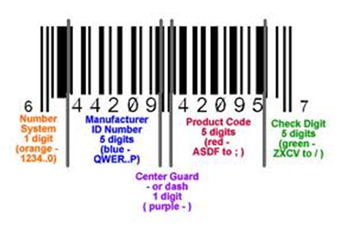

GS1 US www.GS1US.org is the USA administrator of the Universal Product Code (UPC) barcode (as shown to the left) and an information standards organization that brings industries together to solve supply chain problems through the adoption and implementation of GS1 Standards. Nearly 300,000 USA businesses in 25 industries rely on GS1 US for trading-partner collaboration and for maximizing the cost effectiveness, speed, visibility, security and sustainability of their business processes. GS1 US www.GS1US.org is the USA administrator of the Universal Product Code (UPC) barcode (as shown to the left) and an information standards organization that brings industries together to solve supply chain problems through the adoption and implementation of GS1 Standards. Nearly 300,000 USA businesses in 25 industries rely on GS1 US for trading-partner collaboration and for maximizing the cost effectiveness, speed, visibility, security and sustainability of their business processes.

Consumer goods businesses are especially focused on keeping track of product throughout the manufacturing and supply chain cycle. Such information gathering is critical for the grocery, pharmaceutical and automotive parts industries. Groceries and pharmaceuticals must comply with FDA regulations, while automotive companies need strong information gathering systems to track product throughout its life cycle. In the event of recalls, this tracking information can be critical to consumer safety.

In a recent byline article written by Josh Roffman, Vice President of Marketing and Product Management at Loftware, a global market leader in Enterprise Labeling Solutions, he points out that Enterprise Labeling Solutions enable customers to quickly and efficiently make changes to meet regulatory standards, become compliant, and to avoid costly fines and ultimately lost business.

The following is a summary of Mr. Roffman’s article entitled “5 Key Business Drivers for Labeling in a Global Supply Chain”. The complete article can be downloaded at: http://resources.loftware.com/7-Key-Business-Drivers-Brochure.html?utm_source=SupplyDigest&utm_medium=Online-Publication&utm_campaign=Article-7_Key_Business_Drivers

|

|

As supply chains become more global and complex, the effect of regulations and emerging standards can have a significant impact on business. Labeling is a specific area where constant change is necessary to comply with these evolving standards, especially those where labeling and identifying parts and packages can play a critical role to consumer’s safety. Some examples of regulatory standards impacting a wide range of industries today include:

|

|

GHS (Globally Harmonized System of Classification)

GS1 (General Specifications) Standards

UDI (Unique Device Identification)

DSCSA (Drug Supply Chain Security Act)

RoHS (Use of Hazardous Substances)

|

1. Enterprise Labeling for Meeting Regulatory Standards

|

|

Supporting Labeling Consistency – Replicating data from enterprise applications to labeling systems introduces risk for ensuring compliance. Enterprise labeling solutions remove the threat of mislabeling and ultimately non-compliance, allowing suppliers, contract manufacturers, and business partner’s access to centralized data to produce labels remotely. |

| |

|

| |

Enabling Rapid Labeling Changes – Deadlines are critical when meeting compliance. Flexible design capabilities empower business users to quickly and simply make mass label changes without requiring coding from IT or waiting for software release cycles. |

| |

|

| |

Managing Regulatory Variations – It’s also necessary to support extensive variability brought on by the complexity of regulations, products, geographies, and languages. Business rules logic empowers companies to address current regulatory requirements, and account for customer requirements, while providing agility to quickly and easily react to future changes. |

| |

|

2. Providing Competitive Advantage Through Improved Customer Responsiveness

Can You Quickly Accommodate Customer Needs and Requests? - Customer responsiveness is the ability of a business to recognize and respond immediately to changing customer needs.

Changes to labels are always being driven by customer-specific requirements. Businesses failing to meet those requirements in a timely fashion find themselves with dissatisfied customers that will likely turn to competitors. Businesses that view labeling as a key enabler in customer responsiveness, find increased opportunities to serve their client base and drive revenue.

|

|

Providing Speed/Flexibility – Flexible design capabilities empower business users to quickly and simply manage label design and changes. With a solution that offers WYSIWYG design and browser-based capabilities, business users are able to take ownership of the design process eliminating the need for IT to get involved and write code to handle new label creation and label changes. |

| |

|

| |

Meeting Regulatory Standards – As organizations are required to adhere to new regulatory standards, it’s important to maintain a solution that allows customers to easily create new or modify existing labels. Enterprise labeling offers all of the symbologies, tools, and integration to sources of regulatory data to make sure you’re able to meet the needs of evolving requirements. Centralized label management can help ensure that your labeling has consistency and that your company is adhering to regulatory guidelines throughout your company’s global supply chain. |

| |

|

| |

Supporting Global Expansion – Today, companies need to meet the rigors of their customers’ global requirements, such as languages, images, formats, and printers, and to manage variability across multiple industries and regions. Business rules functionality allows customers to handle a greater degree of labeling complexity and to easily configure labels and enable variations in geographies and language in a single place. |

3. Driving Efficiency Throughout The Supply Chain

With today’s supply chain becoming more complex and global in scale, it has become increasingly challenging to ensure responsiveness and efficiency throughout the supply chain. Labeling is a critical factor when considering a business’s ability to quickly and seamlessly distribute products from supplier to customer. To ensure an effective supply chain strategy, companies must consider how labeling intersects with evolving demands such as globalization of manufacturing, safety and quality of products, shorter lead-times, lean business environments, and changing market demands.

In today’s modern supply chain, every product and shipment includes a barcode label, incorporating all of the information necessary to ensure that each item moves throughout the supply chain at the intended speed, and to the intended destination. This makes labeling a mission-critical component of the supply chain where disruptions in areas such as manufacturing, inventory, receiving, and shipping can threaten production and distribution and result in hefty fines, loss of customers, and ultimately result in millions of dollars of lost revenue.

|

| |

Avoid Costly Downtime – It’s important to understand that labeling is mission-critical to the supply chain and that a labeling system failure can mean a stop in production. When production stops, extensive downtime means lost revenues and costly fines, not to mention customer dissatisfaction. |

| |

|

| |

Extending The Capabilities of Supply Chain Partners – An enterprise labeling solution enables businesses to increase collaboration and extend labeling to partners to make sure their labeling requirements are met while avoiding the cost of relabeling goods upon receipt. These solutions allow suppliers to access a centralized solution so they can print labels remotely, fostering efficiency in the supply chain and ensuring labeling and brand consistency. |

| |

|

| |

Automate Labeling – Enterprise labeling solutions offer an alternative to time-consuming manual labeling, which can reduce supply chain efficiency and increases incidence of mislabeling. Find a solution which can automate labeling by integrating directly with enterprise applications and triggering labeling via existing business processes, while ensuring that label data comes directly from the sources of truth for label data. At the same time, labels can be designed and updated by business users, which provide greater speed and flexibility, enabling rapid labeling changes. |

| |

|

4. Protecting the Supply Chain Through Business Continuity

Natural and man-made disasters, whether a storm, a flood, a fire, or geopolitical unrest can wreak havoc with a company’s supply chain and have significant financial consequences. Companies with worldwide operations that include manufacturing and distribution facilities across the globe must ensure continuous flow of goods to customers without interruption. However, when it comes to business continuity, companies most often think about manufacturing and shipping but frequently overlook an essential element - labeling. Even when issues with production and distribution are addressed, if products cannot be labeled during a crisis, continuity is still broken.

|

| |

Enabling a Shift in Label Production – Companies must be able to shift label production from one facility to another rapidly, while leveraging the correct data in order to keep the supply chain flowing. Enterprise labeling solutions enable users to leverage label templates from other locations to minimize the impact on the supply chain during a disruption. |

| |

|

| |

Providing Data/Systems Centralization – Allowing multiple facilities and/or suppliers access to centralized data to seamlessly produce labels remotely is crucial to business continuity. Enterprise labeling solutions provide the ability to connect and integrate to all key sources of label data. Businesses can drive label production from any remote sites utilizing a centralized approach to label data. |

5. Enabling Business Opportunities Through Enterprise Collaboration

Supply chain collaboration allows global businesses to reduce costs and add value for business partners such as suppliers, contract manufacturers, and third party logistics providers. Companies that understand the importance of sharing information and aligning processes for collectively generating, communicating and refining information are able to streamline business to improve efficiency, increase productivity and respond more readily to any business issues. Further, companies that share a common language and approach are able to communicate effectively with business partners to realize revenue-generating opportunities, cost-cutting strategies, recommendations for productivity, and more. When it comes to developing a structure for an enterprise to facilitate collaboration across the supply chain, labeling must be considered as part of the framework.

|

|

Final Thoughts

If you are a retailer, a consumer goods manufacturer, a logistics consultant, software provider, or material handling vendor – or anyone connected to those areas – you know that the GS1-128 (formerly UCC-128) serialized shipping container bar code that uniquely identifies each carton/container is critical to logistics operations. This is especially true in warehousing and distribution centers where they are used to drive internal operations. In the logistics environment, compliance with all labeling regulatory standards is mission critical.

|

|

|

|

Recent Feedback |

Good article. Barcode verification is also an important component of supply chain efficiency and avoidance of down time--and a very often neglected aspect until there is a problem.

John Nachtrieb

Principal

Barcode-Test LLC

Oct, 23 2014

|

|

|

| |