|

|

|

Featured Sponsor: CDC Software

|

|

Learn How Tier One Automotive Achieved Customer, Supplier & Inventory Alignment

For Their Global Parts Operations Center While Reducing its Inventory by 25%!

|

| |

|

|

|

|

|

|

|

| WEDNESDAY'S VIDEOCAST |

| Videocast Series: Operations Rules - Delivering Customer Value Through Flexible Operations

Part 3: Mitigating Supply Chain Risk from the Known-Unknown to the Unknown-Unknown

Featuring David Simchi-Levi, Professor of Engineering Systems at MIT

Wednesday, April 20, 2011

|

|

| UPCOMING VIDEOCAST |

Upcoming Videocast:

Vendor Compliance 101: It's about Supply Chain Excellence, not Chargebacks

How Top Retailers Successfully Develop Programs that Leverage Vendor Compliance For Lean Supply Chain Benefits

Featuring Gough Grubbs, SVP of Distribution & Logistics for Stage Stores, Greg Holder, CEO of Compliance Networks

Tuesday, April 26, 2011

|

|

| NEW! UPCOMING VIDEOCAST |

Upcoming Videocast:

Harry & David Moves from Best-of-Breed WMS to SAP Extended Warehouse Management

Case Study on Why One Leading Company with Complex Distribution Requirements

Is Making the Move to SAP

Featuring Prashant Bhatia, Solution Principle for Supply Chain Management at SAP

and Heather Krupp, SAP IT Development Manager at Harry & David

Tuesday, May 3, 2011

|

|

| NEWS BITES |

This Week's Supply Chain News Bites

- Only from SCDigest

|

|

|

|

| AUTOMOTIVE CASE STUDY FROM CDC SOFTWARE |

Achieve Customer, Supplier

& Inventory Alignment

Learn how Tier One Automotive Achieved Customer, Supplier & Inventory Alignment for their Global Parts Operations Center while reducing its inventory by 25%!

|

CARTOON CAPTION CONTEST

CONTINUES THIS WEEK! |

April 4, 2011 Contest

|

See The Full-Sized Cartoon and

Send In Your Entry Today !

|

|

|

|

| JOB OPPORTUNITIES |

|

Softeon, a rapidly growing provider of WMS and related supply chain software solutions, is looking for Project Managers.

Ideal candidates will have solid knowledge of distribution and logistics processes, excellent communications skills, and be able to manage customer projects end to end.

May consider some recent graduates with

related degrees as trainees.

Position in based in the Northern Virginia area

Respond Here

|

| ONTARGET e-MAGAZINE |

|

|

|

|

NEW! EXPERT CONTRIBUTOR

FROM MANAGEMENT DYNAMICS

|

By Nathan Pieri

Senior VP Of Marketing & Product Management

Management Dynamics

Five Ways to Prepare for

Global Supply Chain Disruptions

|

|

NEW! EXPERT CONTRIBUTOR

FROM VOXWARE, INC. |

By Scott J. Yetter

President

Voxware, Inc.

|

|

|

|

|

| What we See in S&OP 2011 |

Sales & Operations Planning (S&OP) is one of the most interesting topics in supply chain - in part because it is on a path to supersede the supply chain.

There is no question that many companies have become very, very good at the process; many have been at it for some two decades. I once heard a senior Dell official say that "S&OP is a religion" at the company, and that was about 10 years ago, if I remember correctly.

Yet...given the number of conferences, books, articles, consultants, etc., that continue to address S&OP, it seems to me there must still be a quite a few companies that are very new to the process, or at least feel they have a lot of room for improvement. Some it appears haven't even started, despite the overwhelming evidence of the benefits - one might actually say the necessity - of S&OP.

But even companies that would rate themselves very high in maturity always seem to be looking for new ideas from whatever source they can find that will further improve their own efforts. As with most things in supply chain, the definition of excellence in S&OP naturally continues to evolve.

| GILMORE SAYS: |

"For now, supply chain will still be the focal point for most of the thought leadership on S&OP. You can find only little on S&OP in financial circles, and almost nothing in sales and marketing channels."

WHAT DO YOU SAY?

Send us your

feedback here

|

Those thoughts come with the latest release of our Supply Chain Digest Letter, focused this time in S&OP. That's a 16-page report we put together focused specifically on one topic, this time Sales and Operations Planning.

Many of you will have received a hard copy in the mail. If you didn't, you can find one here: SCDigest Letter on S&OP 2011. Even better, as always you can visit our Full S&OP Information Center, which has the Letter plus video, white papers, cases studies and more.

One of the interesting S&OP trends is a battle of nomenclature, but there is some deeper meaning behind that terminology skirmish. For some time but now gaining steam recently, many are pushing the term "Integrated Business Planning" or IBP as the correct name and concept for the process.

We go into more detail in the Letter, but I think the basic idea can be summed up like this: S&OP really has its roots in supply chain, and tends to have a great deal of its focus on the important exercise of balancing supply and demand plans.

IBP, on the other hand, is really about creating alignment to meet the company's financial goals. Supply-demand balancing is a necessary but not sufficient component of that goal. What is critical - and often left out of "traditional" S&OP - is aligning the supply and demand plans more tightly with the company's financial plan and goals.

Gartner calls IBP a "more highly evolved form" of S&OP. Fred Baumann of JDA Software notes that "You could have a perfectly balanced unit-based supply-demand plan and totally fail to meet shareholder expectations."

In the end, by whatever name you call it, it means S&OP/IBP is simply that way you manage the business, not just supply and demand.

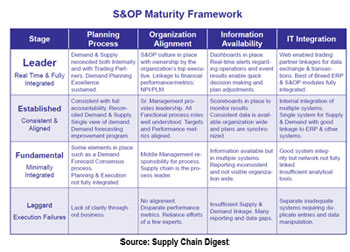

That idea can be clearly seen in the S&OP maturity model below. There is probably no area of supply chain that has seen more maturity models than S&OP, but two years ago when we did our report on integrated planning and execution, we couldn't help ourselves. The model below was developed in partnership with Bob Nardone, former supply chain executive at Unilever who led the effort there to get really good at S&OP.

|

View Full Size Image

|

As can be seen, as a company reaches a higher level of maturity, the process becomes more core to overall business and financial planning, and much less focused on supply and demand per se.

It is led by senior company executives, not the supply chain.

I personally believe the term S&OP will largely stick. But while supply chain side of the house continues to the driver in getting S&OP off the ground in an organization most of the time, the evolution to the IBP process if not name means supply chain's role will inevitably diminishes, to an extent. The natural "lead" for IBP, it seems to me, is finance, and in a small but growing number of firms the CFO does "own" the process.

But for now, supply chain will still be the focal point for most of the thought leadership on S&OP. You can find only little on S&OP in financial circles, and almost nothing in sales and marketing channels.

Some other key S&OP trends worth noting:

We continue to see a more explicit focus on inventory planning as part of the process in many companies, or what some call Sales, Inventory and Operations Planning (SIOP). That practice is important, and a big change in process, but I don't think the term SIOP will really last. Inventory planning will just be part of S&OP.

S&OP has some parallels to Lean, in that some "purists" have argued that S&OP was really about the processes, and that too much technology support just gets in the way of that. I think it is clear that is changing, as the complexity of the business environment, the need to understand the impact of decisions in one area on everything else, and the need to manage risk and the compare results of different scenarios means leaders understand a rich technology platform to support S&OP is really a necessity. This is actually quite a change from even five years ago, where spreadsheets were often viewed as good enough.

For consumer goods manufacturers and retailers, there is a growing focus on connecting the Collaborative Planning, Forecasting and Replenishment (CPFR) process with S&OP - something which somewhat inexplicably few had been doing until recently. The story of how Lowe's and Whirlpool have not only done this but turned it into a truly joint S&OP process between the two companies is a truly powerful one that will be detailed here before long. It's the model for the future.

There is a lot more, but think we will end it here. Think you will enjoy the S&OP Letter and the Information page. Would love your thoughts on the current and future state of S&OP.''

S&OP versus IBP - does the name matter? Is there an important difference in the concept, regardless of the name? What do you see as the key S&OP trends? Let us know your thoughts at the Feedback button below.

View Web/Printable Version of this Page |

| |

THIS WEEK ON DISTRIBUTION DIGEST |

Holste's Blog: DC Automation Raises Operational Complexity Issues For Many Companies

|

|

Top Story: Supply Chain Video - Trends in Software for Voice Applications

|

|

Top Story: Gene Gagnon Classic ''Supervising on the Line'' Updated and Re-Issued for 2011 |

| |

|

|

READER QUESTION |

Question: Are there guidelines for when a company should move from plant shipments to a consolidation DC? Question: Are there guidelines for when a company should move from plant shipments to a consolidation DC?

See our Expert answers here.

Add your input - we could use some more!

|

|

| Q: |

How many SKUs/Items are stocked at an average Walmart Superstore? |

| A: |

Found at the Bottom of the Page |

|

|

|

| YOUR FEEDBACK |

We're publishing some very recent letters this week stemming from editor Dan Gilmore's blog post last week on Geiger Counters for the Supply Chain?, which pondered the potential problems business face if even trace amounts of radiation were detectable in products coming from Japan.

That includes our Feedback of the week from Ralph Salier-Hellendag, a "business anthropologist" with some very interesting thoughts on the subject. You will find that letter and several others below.

Feedback of the Week - on Geiger Counters for the Supply Chain:

Given our sensitivity to radiation, I would not be surprised that any thing from Japan will be view as suspect for the time being and until the facility over there is "capped". Americans have a great underlying fear of radiation and are quick to avoid it wherever possible. Even to the point of having their granite counter tops tested and removed if there is any sign of radiation. While this fear is present, it is poorly understood and "even made fun of" with a great risk to anyone who tries to sell any thing that could be contaminated.

No one really knows what a safe amount of radiation is and this is the basis of much of this fear. While there is radiation all around us all of the time that we are totally unaware of, once we have a heightened awareness, it does not subside for quite a long time. It would behoove those importing items from Japan to demonstrate a before and after reading of radiation if they can to prove to their customers that it is not an issue.

My background is that of a Business Anthropologist. I study the effect of such things on business systems and on the culture as a whole. For Americans there is an underlying fear that the radiation plume from Japan will come to the US and we will not have the necessary protection.

Some companies that get material from Japan are now very concerned that the parts and supplies will be contaminated (The Toyota plants in the US have already shut down and are awaiting the results of tests being done on parts from Southern Japan). Those from the north are also being tested but most were shipped before the accident. Others are being rejected out of hand. And it doesn't just effect Toyota, many US car companies import parts from that part of the world and are very worried. Food stuffs, glass ware, electronics etc...

Are all suspect and are being tested. The issue however is the validity of the testing, the transparency and our general distrust of the government to do things right #1 and then tell us if there is something wrong #2. It is an interesting predicament.

Ralph Salier-Hellendag

ONEOXY Services Team

More on on Geiger Counters for the Supply Chaion Geiger Counters for the Supply Chainn:

Like it or not, this threat is real.

Special customs processes should be initiated for all cartons, boxes, inner packs, and items coming from Japan. Are there any plans? I don`t think I would be musing over this during dinner, (and as you know, I regard myself as a fun guy).

Mark Shuda

Absolutely, companies who are purchasing product internally have a responsibility to insure that they are safe whether it's for this particular reason or others. This was brought to light when the children's toys were discovered to have toxic paint.

If companies choose to ship or manufacture products from wherever, they do have the responsibility for quality assurance. Consumers are less tolerant currently for exposed radiation products or toxic products. As consumers become more aware, they will be more likely to rebel against such products. As I say this, I think of all the intelligent people that still smoke :)!

Susan Rider

Rider & Associates

The manufacturers need to get out front of this issue as the recent news out of Japan is quickly raising the fears of the consumer. With recent reports of radiation in area fish, and news that the water gushing into the Pacific had radiation levels millions of times above the regulatory limit, any product that comes out of any ocean is going to going to give the consumer reason to pause.

Letting the consumer know that the product has been safeguarded and proactively letting the consumer know the product has not been tainted with radiation will help to alleviate some consumer fear.

Larry Negrich

Retail Business Development Consultant

Avnet Technology Solutions

Of course companies should be thinking about every safety aspect that affects their products. Toxicity comes in many forms, and many U.S. importers and domestic manufacturers have been exposed as inept at ensuring that their products are safe in all the ways they should be safe. The weekly published recall lists are staggering. The effort to "get the lead out" is still an ongoing effort in China and here after more than a decade of publicity. Poor Toyota, first with their millions of recalled vehicles and now suffering the events in their homeland. Poor parents of babies that guillotine themselves with sliding crib slats.

So now we have another product concern: Potential radiation beyond the levels we endure daily from natural sources. What are the daily levels we endure from sunlight and the ground (yes, the ground)? Put a number on it. How much radiation did our Astronauts receive in space without negative effects? If we're going to deal with this new concern, we need to understand it better.

Retailers need to help their customers understand it better. Perhaps a well-crafted and informative TV campaign from the National Chamber Of Commerce, FMI, or other retailer groups. It's a prudent first step, to be followed by continued education and product monitoring. But first, stem any mindless, uninformed panic.

Not to be flippant or unfeeling, but remember that Godzilla was born in the minds of Japanese survivors of the bombs we dropped on them during WWII. A monster created by radiation. Now we have the potential of creating another radiation monster--unless we get in front of it with information and education.

M. Jericho Banks

President, CEO

Forensic Marketing LLC

|

| |

|

| SUPPLY CHAIN TRIVIA |

| Q: How many SKUs/Items are stocked at an average Walmart Superstore? |

| A: 142,000 currently, now scheduled to rise by some 8500 as Walmart reverses course on SKU rationalization. |

|

Copyrights © SupplyChainDigestTM 2003-2010. All Rights Reserved.

SupplyChainDigest

PO Box 714

Springboro, Ohio 45066

POWERED BY: XDIMENSION |

|

|

|

|