SCDigest Editorial Staff

| SCDigest Says: |

SCDigest has compiled a list of symptoms that may indicate your global sourcing strategy and execution needs a tune-up. SCDigest has compiled a list of symptoms that may indicate your global sourcing strategy and execution needs a tune-up.

Click Here to See Reader Feedback |

The world has gone flat and global, and it is almost difficult to have a sourcing and market strategy today that does not involve globalization.

Still, stories are prevalent of companies that are not fully pleased with their global sourcing strategies and results.

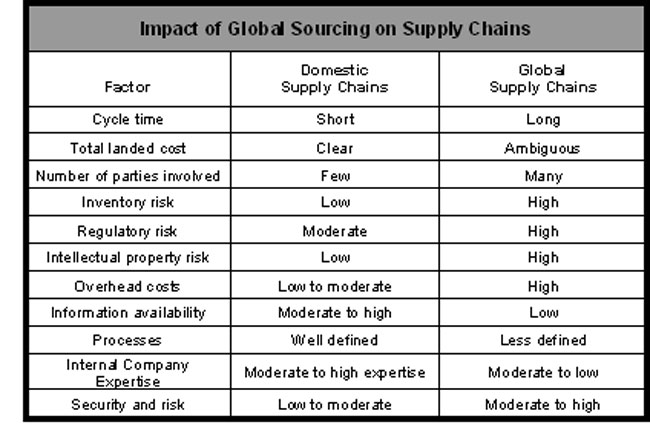

Of course, global sourcing is not easy. As shown the in chart below, cost and complexities rise along many dimensions when moving from domestic to global sourcing.

Source: Supply Chain Digest

(Global Supply Chain and Logistics Article - Continued Below) |