Gainsharing Made Simple

Kelley and Hounsell say that the easiest and most effective way to turn this situation around is to implement a gainsharing program with DC operators.

Gainsharing in general refers to any program where improvements in some operational area (profits, costs, etc.) are shared between the company that achieves the results and some other party, such as a consultant or, in this case, shop floor employees.

Kelley and Hounsell argue that most traditional corporate gainsharing programs are too complex for both management and employees to work effectively in logistics. So, they argue for a very simplified model that they say is easy for DC employees to understand.

Naturally, some metric needs to be selected for each worker or area of the DC. While more formal engineered standards can be used, and are likely to be most effective, more traditional DC metrics such as lines or case per hour can also be used.

The fundamental point is that by offering DC employees an incentive to improve productivity on the chosen metric in a way that benefits both the company and the employee, substantial productivity gains are possible.

In general, a plan that lets the company keep two-thirds of the savings from productivity gains and employees one-third should work out well for both sides, Kelley and Hounsell argue.

But the program can be staggered to get there.

After a baseline rate is set (whether though historic analysis, engineered standards, or other approach), it is fairly easily to develop a “sliding scale” of increments to the employee’s base hourly wage based on their individual performance. Actually, what Kelley and Hounsell propose is almost a reverse sliding scale – employee incentives actually accelerate as higher and higher levels of productivity are achieved.

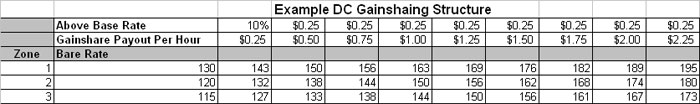

The table below, taken from the book, offers one example of how such as gainsharing program could be structured.

A few points are key. First, in this example, the company keeps a greater percent of the productivity savings at lower levels, and the employees relatively more as rates above the base level increase, eventually reaching something close to the ideal two-thirds/one-third ratio.

Second, the next level or step must be hit for the payout to be given. Any gains that fall between steps are totally to the company’s benefit.

Third, there are no limits.

“Tell your employees you encourage them to double their productivity, because the sky is the limit to the bonuses you want to pay out,” Kelley and Hounsell say (within the confines of acceptable quality and safety).

Of course, that “sky is the limit” approach is likely to send corporate accountants into a fit, worried about giving away “free money.” Kelley and Hounsell offer recommendations on handling that and a number of other issues, which we will summarize next week.

Overall, such a program provides “an unstoppable impetus to create significantly increased profits” the authors say.

That sounds pretty good in these times.

Is a simplified gainsharing approach an easy way to reduce logistics costs? What are the downsides to such a program? Let us know your thoughts at the Feedback button below.

|