SCDigest

Editorial Staff

| SCDigest Says: |

That system allows the data collected via RFID reads to be linked to specific purchase or delivery orders from VW, addressing one of the challenges of RFID systems between companies – how to connect the RFID tag data with other information to make it meaningful. That system allows the data collected via RFID reads to be linked to specific purchase or delivery orders from VW, addressing one of the challenges of RFID systems between companies – how to connect the RFID tag data with other information to make it meaningful.

Click Here to See Reader Feedback

|

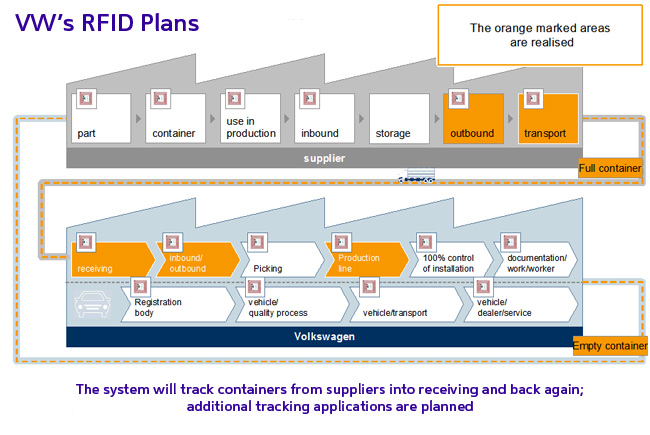

Volkswagen, the German automaker, announced last week that it was rolling out an RFID-based tracking system for incoming parts from suppliers after a successful one-year pilot program. With the plans, the company says it will be the first automaker to employ RFID in moving parts through the supply chain.

The system is being rolled out based on RFID software and services from IBM, and tags and readers from Intermec.

The application takes advantage of an existing supplier portal that already connects suppliers with Volkswagen. That system allows the data collected via RFID reads to be linked to specific purchase or delivery orders from VW, addressing one of the challenges of RFID systems between companies – how to connect the RFID tag data with other information to make it meaningful.

Initially, suppliers will use handheld readers to scan RFID container IDs, which are associated with the specific items inside the containers based on the purchase order and what is actually being shipped. Volkswagen will scan the containers when they arrive to automate the receiving process. It will also track empty containers as they move back to suppliers, meaning the system will provide asset tracking benefits in addition to improving receiving processes and supply chain visibility to inbound goods.

(RFID and Automatic Identification Article - Continued Below)

|