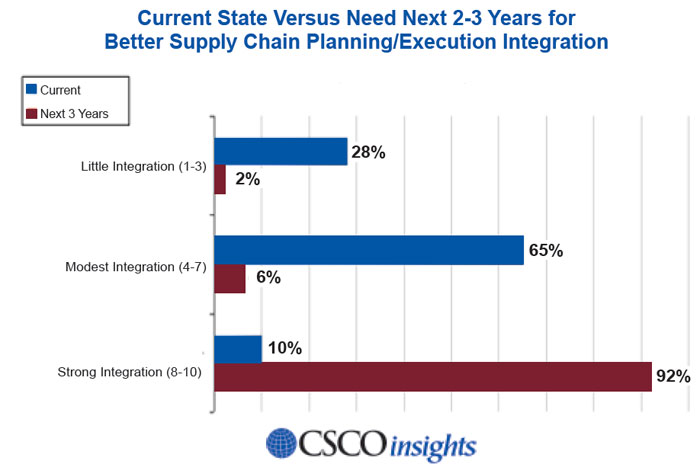

In contrast, an amazing 92% of respondents say their companies need to get to a high level of integration of supply chain planning and execution in the next 3 years. (See graphic below.)

Information Availability will Change Supply Chain Processes

Companies are facing a myriad of incredible challenging business and supply chain issues. Those include brutal global competition, growing supply chain complexity, the need to both source and develop markets worldwide, extreme pressures to reduce cost, shortening product lifecycles, volatile demand and input costs, and many more.

At the same time that companies are facing these supply chain pressures, profound changes are occurring in the availability of information that can dramatically impact supply chain processes.

The days of serial, hierarchical information flows are nearly at an end. Today, we are already in the early stages of the real-time supply chain, where information about supply and demand is not only visible and available in near-real time, but can easily be shared broadly within the enterprise and with its trading partners.

As Nick LaHowchic, former president of The Limited Brands’ Logistics Services unit, and Dr. Don Bowersox of Michigan State University recently wrote in their insightful book Start Pulling Your Chain – Leading Responsive Supply Chain Transformation: “A many-to-many supply chain architecture offers the potential for all participating in the “network” to simultaneously share identical information across the entire supply chain in real-time…The advent of simultaneous real-time visibility constitutes an enormous technological breakthrough having far reaching implications.”

We are indeed at the start of the “zero latency” world, the ramifications of which we are only beginning to understand.

As a result of all these forces, and our growing understanding of what makes supply chains work effectively, we must rethink our approach to planning and execution.

For many years, the industry has divided the supply chain landscape into “planning” and “execution” processes. Supply Chain Management was organized to support the internal processes of “plan,” “source,” “make,” and “deliver.” This created functionally driven supply chains and operational silos that failed to connect the network as customer back to supplier. This conceptual framework served as an underpinning for how software vendors were “organized” (e.g., “supply chain planning” vendors and “supply chain execution” vendors), how companies organized themselves internally, and how processes were designed.

But that world is changing. While we will always have “planning and execution,” the two processes must clearly become more integrated, and be seen more directly as simply different ends of one long supply chain process continuum, more so than distinct functions and processes. As with any continuum, the edges between adjacent points on the line are blurred, not sharp.

While there are and certainly will continue to be differences between, say, long-term strategic supply chain planning and supply chain network planning (on one end of the continuum) and very execution-focused processes such as direct store delivery of consumer goods to retail on the other end, in the middle, the distinctions between planning and execution processes will begin to dissipate.

In a “sense and respond” supply chain, just what is planning and what is execution? CSCO Insights believes that the distinction between planning and execution in many areas will be increasingly irrelevant, as companies achieve continuous and near real-time feedback loops between the real-world and today’s traditional planning processes.

This change will also help foster and/or require that the functional and process silos that still exist in many companies break down even further. In the end, it will simply be about alignment – having the entire extended supply chain fully and flexibly working together to meet the needs of the business and maximizing profit and shareholder value in alignment with customer demand.

Multi-level, real-time visibility, next generation supply chain decision support and optimization tools, new supply chain organizational models, and increased understanding of how to close the loop between planning and execution will combine to create the next paradigm of supply chain management excellence. Companies should begin to set their sights on this target today.

Do you think supply chain planning and execution can – and will – become more integrated? Will planning and execution start to blur in many respects? What will it take for this to happen? Let us know your thoughts at the Feedback button below.

SCDigest is Twittering!

Follow us now at https://twitter.com/scdigest |