Some buyers are finding the optimization approach can deliver a better result. The report says optimization technology has been used in such commodity categories as food ingredients, packaging materials, chemicals, travel, and many more.

The report says companies are starting to get real results from using sourcing optimization outside of transportation:

- A consumer products manufacturer has found that 10% of its $30 billion annual spend could be enhanced through optimization, and that as much as $120 million in purchase cost savings might be achieved.

- A high-tech firm says it is using optimization for 56% of its annual spend, saving some $600 million.

Other anecdotal evidence suggests that more companies are starting to use sourcing optimization, and those that have tried it are increasing the number of product categories that optimization is used for and sourcing “events” that are held. Overall, the report says savings of about 10% are common versus more manual, traditional approaches.

“There are no simple solutions to an increasingly complex world,” the report quotes on user or sourcing optimization technology as saying.

“Optimization allows buying organizations to build mathematical models that incorporate all bids from all suppliers,” the report says. It will then try to find a feasible” solution, which typically means all requirements are covered, business rules are met, and the answer is the low-cost or nearly low-cost solution.

This example in the report well illustrated how optimization technology could be useful: a large company annually contracted for meeting space within 15 geographic regions, and considered some 750 hotels. In the past, each negotiation was done regionally, with little opportunity for the company or the hotel chains to leverage spend across regions. Now, all bids, including cross-regional proposals, can be considered together.

Another common scenario where optimization might be useful is aggregating demand across business units, each with their own specific products needs and business rules. Manually processing all those needs to leverage total spend with suppliers might be quite a challenge – but quite doable using the optimization approach.

Additional complexity can enter the equation, making it still harder for manual methods to come up with the optimal solution. For example, companies may need to factor in how much they would like to procure from minority or woman-owned businesses, maintain multiple sources of supply and target percentages for each within a category, and factor in Green supply chain or other factors beyond just price.

The report says that an analysis of including or changing these various business rules and goals is done through scenario analysis and usually a key part of the optimized sourcing process.

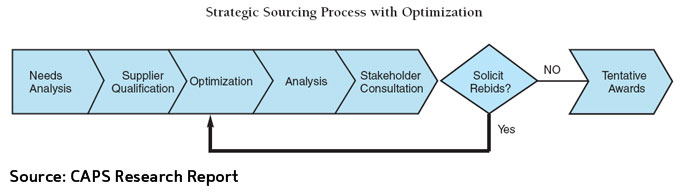

Often, the bid process goes through several rounds, and sellers and buyers refine their bids, rules and awards. (See graphic below).

Small Number of Technology Vendors

A relatively small number of vendors provide sourcing optimization technology, and some are specialized in one area, such as transportation.

The report cites the following list of vendors:

- Ariba/Procuri

- CombineNet

- Emptoris

- i2

- Iasta

- Manhattan Associates

- Perfect Commerce

The full report contains much detail, including how a bid process really works and keys to success, which we will summarize next week.

Do you have experience with sourcing optimization technology outside of transportation? How well does it work, and what are the best applications? What are the downsides and limitations, if any? Let us know your thoughts at the Feedback button below.

|