As it relates to DC automation projects, the Payback Method (see above chart) is the method most commonly used for calculating Return-On-Investment (ROI). Using this method the project is paid for out of labor savings. So, for example, if an automation project can reduce headcount by 10 people (5 per shift in a two shift operation), costing the company an average of $45,000 ea. per year (including benefits), then the project will produce an annual labor savings of $450,000. If the company’s payback period for capital expenditures is based on 3 years, a project costing $1,350,000 can be justified.

Likewise, if more labor can be eliminated, and/or the payback period can be extended, a larger investment can be made. By looking at the project from its potential labor saving prospect, a company can begin to understand what it can justify.

Another approach to getting a handle on how much to budget for automation is to go to industry trade association meetings and expos. Find companies that are similar in size and scope, that have recently automated, and inquire as to what they did and how much they invested. The new MODEX 2012 Show in Atlanta starting February 6th presents a great opportunity to attend seminars, gain perspective and insight from companies that have already automated, and see over 500 exhibitors. The show is free to attendees, see -

"Material Handling Association Aims to Broaden Reach with New MODEX Show in Atlanta in February."

Hiring an independent consultant or industry expert to assist in this preliminary evaluation and planning stage can be beneficial in getting the project off to a good start.

The Phased-In Approach

If justifying the entire automation project at one time is problematical, it may be beneficial to consider implementing the project in phases. By deferring some of the investment to a future date, growth in volume along with incremental increases in labor may improve ROI opportunities down the road. If justifying the entire automation project at one time is problematical, it may be beneficial to consider implementing the project in phases. By deferring some of the investment to a future date, growth in volume along with incremental increases in labor may improve ROI opportunities down the road.

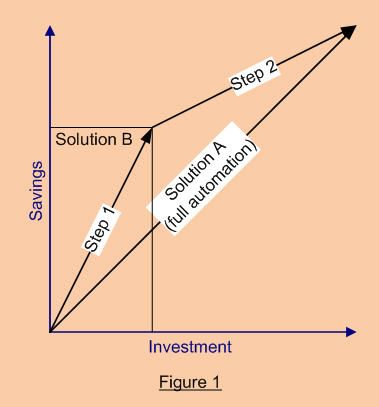

An important part of evaluating a phased-in approach is to examine its cost/benefit ratio. Figure 1 compares two hypothetical solutions, A & B.

Solution A represents going to full automation in a single step. The alternative method, Solution B, involves approaching automation in two steps or phases.

In the example shown, taking the first step will provide about 60% of the savings generated by full automation, but at only about 35% of the investment.

This may be possible for some projects by implementing a WMS in step 1 which would improve receiving efficiency and accuracy, provide for directed put-away and retrieval, cross-docking, and improve order picking operations just to mention a few. Then in step 2 an integrated automated system solution could be deployed.

Staying in Business While Implementing an Automation Project

Another important consideration a company should give some considerable thought to in the planning stage, has to do with managing the business while implementing an automation project. Obviously, the company must continue to pick and ship orders while the new system is being installed. This requires careful and meticulous planning. If the business experiences seasonal peak periods, the project implementation schedule may need to be adjusted to minimize disruptions during those periods. This may affect how long it will take to complete the project, which could have further cost and sales implications.

The risk of inconveniencing customers during the critical installation and switchover period is real, especially if something unplanned for happens (Murphy’s Law). Therefore, the company needs to evaluate the risks and develop a strategy for managing the unexpected. This may include building backup inventory at an off-site location.

In any event, explaining to your customers what you are planning, the projects expected benefits for them and the company, and keeping them informed on how the project is progressing, may help to alleviate some of their concerns.

|