As we cruise into a Holiday weekend here in the US, some thoughts on a subject I covered many years ago, and that’s the idea of “Stapling Yourself to an Order.”

The notion was first popularized in a classic Harvard Business Review article dating all the way back to 1992 by Benson Shapiro, Kasturi Rangan, and John Svioloka (Shapiro the most well known of the trio.) The piece has been republished as a “classic” by HBR a couple of times since then.

“The truth is that every customer’s experience is determined by a company’s “order management cycle” - the ten steps, from planning to post sales service, that define a company’s business system,” the article says early on.

For awhile, there were some order management vendors in the market which used to talk about the concept that “the order is king.” You don’t hear that much anymore, and I am not sure why – except I did hear it last year from Rick Odorico of building products supplier Dal-Tile, who unprompted used that exact phrase in a Videocast we broadcast last year.

In general, we have certainly become better and much more highly automated in the traditional order management process since 1992, when Shapiro, Kasturi, and Rangan wrote that “Each step in the OMC requires a bewildering mix of overlapping functional responsibilities…Each step is considered the primary responsibility of a given specific department, and no step is the sole responsibility of any department.”

Gilmore Says:

|

|

"For many companies, there is a lot of good that could be done from re-stapling yourself to an order, maybe not in the physical sense of the paper orders we had back then, but with the same conceptual foundation of following your version of the OMC from start to end."

What do you say? |

|

Send us

your Feedback here |

|

By the way, here are the 10 steps of the Order Management Cycle that the article defined:

• Order Planning: Design of the order management process

• Order Generation: How and where orders will be solicited and acquired

• Cost Estimation & Pricing: Providing quote or price to customers

• Order Receipt & Entry: Capturing a new order and starting the workflow (manual or automated)

• Order Selection & Prioritization: What orders are most important, and how will they be handled sequentially?

• Scheduling: Moving the order into a production or fulfillment plan

• Fulfillment: Delivery to the customer

• Billing: Customer invoice process

• Returns & Claims: Handling any returns or complaints about damage or other product issues

• Post Sales Service: Service and support activities (warranties, replacement parts, etc.)

There is a certain “timelessness” to these 10 steps, and certainly they can be used as a starting point to document a company’s own order management process. The article makes the axiomatic point that “every time the order is being handled, the customer is being handled at the same time.” (As an aside, I have a copy of the original HBR article, and just might be able to send you a copy upon request at the Feedback button below, assuming the numbers aren’t so large as to have Harvard Business Press attorneys sending letters to us.)

But even today, does any one person in a company have a full grasp of the full order management cycle? Probably somewhat more today than in 1992, for at least major parts of the OMC. Many companies have well defined and executed streamlined “order to cash” processes, as the most obvious example. Technology today can drive more integrated process than software was close to delivering almost 20 years ago, when our latest generation of supply chain managers was still in grade school.

But I am not sure how many companies have a single manager that owns the OMC. And in many, I still think customer service reps probably understand the OMC and its challenges better than anyone else in the company.

As the title the article suggests, I think there still may be lots of opportunity to “staple yourself to an order,” and literally walk through that order management cycle, especially from a customer’s perspective, while also for looking for internal inefficiencies and other areas of improvement.

But there is another important difference between 1992 and today. Back then, we had much higher levels of vertical integration, and sales channels were relatively simple. Today, we have increasing outsourcing, virtualization, and a dizzying array of channels (note: the vending machine channel is coming, as it already has for Apple and others, and is widely used in Japan).

So I posit that today, we have to staple ourselves to a “multi-channel” order as well, which is a bit different that how we might have thought about it in 1992. Stapling yourself to these orders will often involve a more virtual, information-based journey than the almost pure physical one Shapiro and gain were envisioning (though there is much value in that too).

Just think of Amazon.com and now WalMart, Home Depot, and I am sure many others which are vastly expanding the drop ship model, taking e-commerce orders and firing them off to tens of thousands of suppliers. Just imagine the potential for fulfillment variability there.

We in fact wrote a report about this earlier this year, which you may or may not have seen. It is available of course for download: Re-Staple Yourself to an Order Report.

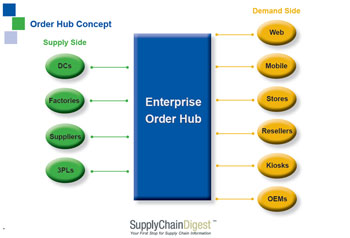

This whole scenario has led a growing number of companies to look to create “order hubs” – central repositories of customer orders that in turn manage the supply and fulfillment sides of the OMC across distributed channels. I don’t have room right now to go into much detail, but here is a very summary illustration from the report:

Larger/Downloadable Image

So I suggest that for many companies, there is a lot of good that could be done from re-stapling yourself to an order, maybe not in the physical sense of the paper orders we had back then, but with the same conceptual foundation of following your version of the OMC from start to end, with a special attention to the complexities of virtualization and multi-channel fulfillment.

If you haven’t done it lately, it may be time to do it right now. Process naturally deteriorate, as most know, and I suspect for many they will find the customer is being “handled” in some ways that could be improved.

Have a good Memorial Day weekend for those in the US.

Though we may have gone electronic, is there still value in “stapling yourself to an order?” Does anyone at your company really own the full OMC process? How is the virtual, multi-channel world impacting this? Let us know your thoughts at the Feedback button below.

Web Page/Printable Version of Column

|