However, growing concern about labor and demographic trends, in combination with recent technology advances, are breathing new life into AGVs in distribution.

Laser-guided systems have increased overall AGV flexibility, as have new control systems capabilities.

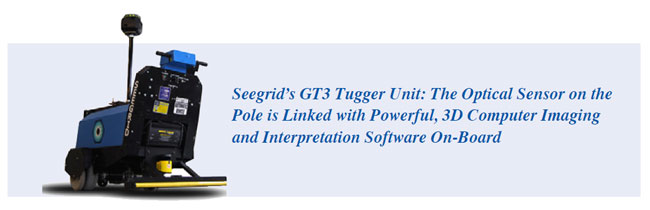

For example, Seegrid Corp. has added optical capabilities to its line of “industrial robots” (AGVs) that increase the flexibility of movement paths and increase safety. Using the optics and other sensors, the software in Seegrid’s robots builds a 3D map of its operating environment. As a result, the robots can generate their own “guide path” for the movement of materials from different points in the DC – and with much less restrictive tolerances for making those moves than traditional AGV technology.

By now, many have seen the technology from Kiva Systems, in which a clas s of AGVs hold pallets of product, and flexibly deliver those goods to stationary pickers for piece or case picking. As a result, any product can go to any operator at any time to fill any order. s of AGVs hold pallets of product, and flexibly deliver those goods to stationary pickers for piece or case picking. As a result, any product can go to any operator at any time to fill any order.

Several AGVs providers, such as Jervis B. Webb, have introduced new AGV systems for automated trailer loading and unloading, using new sensors and control systems that enable them to much more flexibly deal with pallet handling issues inside the trailer.

Distribution Center Applications

Moving forward, as this technology advances, we could well see fewer lift trucks running around DCs and more robotic automation, and perhaps a step closer to highly automated distribution operations.

Likely applications for this type of AGV technology in distribution include:

- Unit load/pallet movement from receiving to putaway drop areas;

- Unit load/pallet movement from drop areas to staging locations;

- Unit load/pallet movement from reserve to forward pick drop zones;

- Unit load pallet movement of materials to postponement/work order processing areas;

- Unit load pallet movement of materials from work order processing areas to staging;

- Replacement of pallet jacks for case picking with automated movement via AGVs;

- Case and piece picking in which the goods are automatically delivered to stationary pick stations;

- Transport of mix-SKU pallets from shrink wrap area to staging; and

- Automatic trailer loading and unloading.

An emerging operational vision might be to focus associates on the task that only they can do – loose case picking, pallet putaway/section into/from pallet storage wrack, etc. – and look for automation to handle the transport task of moving materials long distances across the DC.

This article is based in part on a white paper written by SCDigest on AGVs in distribution. To download a copy of that white paper, go here: New Life for AGVs in Distribution?

Do you think AGVs will have a growing role in distribution? Why or why not? Let us know your thoughts at the Feedback button below.

SCDigest is Twittering!

Follow us now at https://twitter.com/scdigest |