Today’s multi-channel, highly responsive, consumer-focused retail landscape demands a supply chain approach that converts traditional DCs into the equivalent of Minolta’s BizHub.

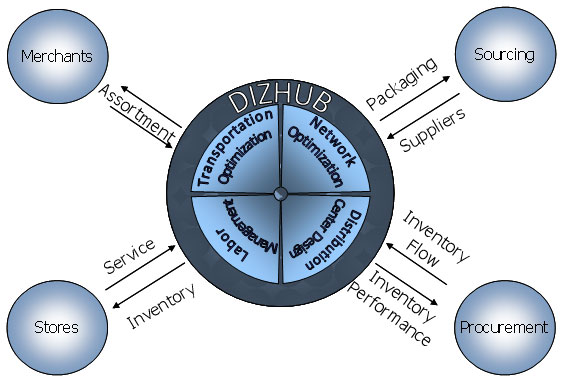

For the sake of this article, we’ll refer to these DCs of the future as “DizHubs.” In the same manner as the BizHub, the evolving DC needs to combine advanced, multi-channel material handling concepts with enterprise-focused process and systems to allow the DC to become the corporate “nerve center,” which optimizes merchandise flow.

The transition from DC to DizHub involves a combination of organizational, process, systems and infrastructure changes that transform supply chain operations from a focus on reactive execution to one of proactive, decision-based planning and enterprise support:

Organization: Organizationally, the successful structure leverages enhanced assortment, product, supply, demand, and operational information flow to support enterprise sourcing and product-flow decision making. This requires an organization that has similar goals across departments, and focuses on sharing information across those departments.

Process: As stated earlier, the process needs to center on proactive, decision-based planning across the entire supply chain network. This includes additional involvement in the decision-making process (sometimes all the way back to the manufacturers), as well as additional decision points in the calendar.

Systems: The systems integrate enhanced forecasting & demand planning capabilities with tools providing real-time visibility of SC-wide inventory availability and movement.

Infrastructure: The infrastructure changes so that each of the individual nodes of the supply chain supports the new needs of the business. For most companies, this means adding new nodes, removing some of the existing nodes and transforming other nodes.

The reconfiguration of an existing network to support these multiple flows and get the most out of the DizHub can be challenging. It will typically involve a phased-in transformation over many years that can include closing existing facilities, opening new facilities, renegotiating vendor contracts and reworking internal capabilities. But in the end, it all comes down to information flow. The successful DizHub communicates with:

- Merchants to decide on the right assortment;

- Sourcing to decide on the right suppliers and packaging configurations;

- Procurement to decide on the right inventory flow strategies to optimize inventory performance; and

- Stores to ensure service, while optimizing inventory investment and margin.

The following graphic shows some examples of the new lines of communication that the DizHub will be handling in these new networks:

|