Dr. Watson Says: |

|

| ...if you want a responsive supply chain, you have to build in enough capacity. |

|

What Do You Say?

|

|

|

|

It is now well-known that the surge in last-minute online orders overwhelmed UPS’s delivery system and UPS failed to deliver products when promised and on-time for Christmas. I’m sure that many more articles will be written that discuss the specifics of what went wrong for UPS.

But, in this article, I’m interested in explaining what went wrong in one general graph and then using that graph to draw lessons for the supply chain.

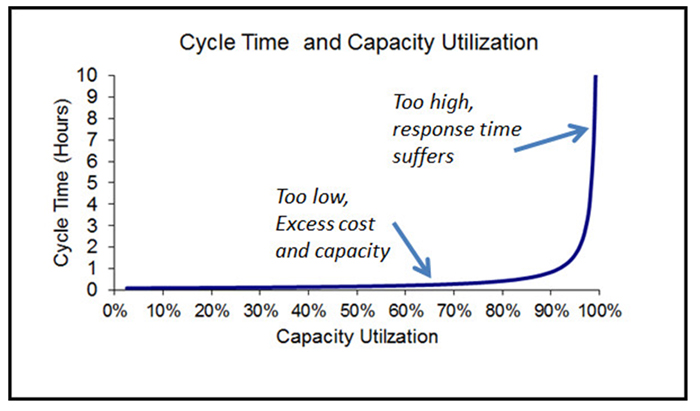

Borrowing from queuing theory, the excellent book Factory Physics tells us that as any system approaches 100% capacity utilization, the cycle time (the time to clear all the orders) grows in a highly non-linear fashion (or, in other words, conditions deteriorate very fast and orders become very late).

The following graph illustrates the point.

Previous Columns by

Dr. Watson |

|

|

This is what happened to UPS. They planned on a certain amount of capacity. Then, when demand was much higher than anticipated, it swamped available capacity and made for a lot of late orders, unhappy customers, and unwanted publicity.

This same graph applies to every supply chain. As you approach 100% capacity utilization, you can expect very long cycle times. Without spare capacity, any variability (in demand or in supply) will cause cycle times to continue to grow.

Also, as you can see by the graph, you may not get much warning of a potential problem. You can see this with traffic on a highway. Even some heavy traffic can seem to move pretty fast (this is 80% capacity utilization), but by the time you get to 95% capacity utilization on the roads, the travel times become unbearable.

If you want to create a responsive supply chain, you have to build in enough capacity. The late Don Frey (who I was lucky enough to have as an advisor) used to say that if you wanted a responsive supply chain, just build another production line. In other words, he was saying that instead of building your capacity to match demand, you should have a lot more capacity—and therefore move the left of the above curve.

This graph also explains why supply chain design can be so difficult. If you don’t have enough capacity, you will have angry customers with late orders. If you have enough capacity to ensure responsiveness, then you may have angry investors who think you are wasting money.

Final Thoughts:

The idea presented here is related to the article on the three types of buffers in a supply chain. Of course, UPS couldn’t buffer the excess demand with inventory (they can’t deliver before you order) and so they were stuck with time being their buffer.

|