|

February 12, 2015 - Supply Chain Flagship Newsletter |

|

| FEATURED SPONSOR: AMBER ROAD |

||

|

||

|

||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

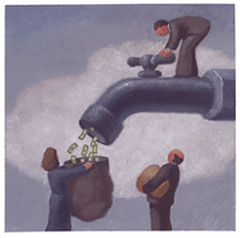

"This is excellent. A couple of points for feedback: Taxes - the global supply network is a critical determinant of the global tax bill that companies pay, in terms of location, value-add operations, facilities, employment, inventory stocking (inventory taxes), etc.," Gopal noted. Equally important, he said, "the traditional notions of inventory as a bad thing are moving fast towards inventory being a competitive weapon, particularly as the cost of capital is so low. And perhaps consider that accountants should now view inventory explicitly in terms of "unsaleable" or waste, "channel stuffing," a definite liability versus a true asset on the books." He also suggested I might have emphasized the increasingly important global trade management requirements (and penalties) and how they have become core supply chain competencies that must be mastered. John Kirkegaard, president of consulting firm DCRA Inc., also liked the column but offered some additional suggestions. "Aligning a cost accounting system around the cash flow, inventory flows, outside commitment flows (e.g. purchasing, contract manufacturing) is a secret weapon for better business management," Kirkegaard wrote us. "Accountants have been trying to do this for years but lack a model to follow. If they would take a lead from a supply chain model to capture cost accounting everyone would win." He also offered what says are "facts" relative to accounting and the supply chain: 1. Measurement of supply chain activities is an early warning look at emerging problems that provides a signal far earlier then "accounting" typically does. 2. An S&OP or supply chain plan should generate a future look at how the balance sheet and income statement will change. 3. Supply chain measurement of inventory flows serves as a great "audit" tool to understand what is happening in the business. 4. Leverage of supply chain excellence in managing lead times can improve working capital positions and create competitive advantage. The very smart David Armstrong of Inventory Curve liked to see my inclusion of the DuPont model to connect finance to the supply chain for these BDO accountants. "I've been using a version of the DuPont model since the seventies. The version I was exposed to was called the Strategic Profit Model (SPM), but it is the same thing," Armstrong wrote. "I believe I was first exposed to it in a seminar put on by Dr. Bud LaLonde of Ohio State. To me, it is one of the most valuable tools around, both for finance people and for those of us in supply chain." He added that "To an extent, I've had similar experiences to yours where I got a lot of blank stares from finance people. When I asked if they were familiar with the model, many have indicated they were unaware of it. I think one of the problems is that the model has typically been presented as a generic model, showing relationships, but void of any data. That makes it too abstract." However, Armstrong says, when you load the with real data, "the financial picture of organizations comes into view in an easily comprehensible way. In one company I worked for, we shared detailed financial information with all of our employees. Using the SPM, we not only shared the data with the employees, but they were able to track their individual job/work efforts all the way to Net Profit and ROI. They got it!" Alan Denholm in California liked my approach quite a bit, but thinks it's time for a new model between accountants and the supply chain."

This is especially true, he says, as supply chain start to encompass cross-company processes. "Accounting systems primarily concern themselves with intra-company data, while supply chains are increasingly inter-company in nature, with complex relationships and trade-offs that accounting has a hard time capturing. Concepts like the costs and value of "collaboration," really have no accounting parallel," Denholm says. Herb Shields of HCS Consulting has been in a similar situation, he tells us. "In 2013, I gave a talk to the Illinois CPA Society on inventory. I asked myself the same question that you did - how in my case can I make inventory interesting to CPAs and what should I suggest they do to influence it," Shields wrote us. "I liked your approach to the broader topic of supply chain, and how you related it to cash and profitability. In both cases - supply chain or inventory- if management outside of supply chain sees the connection to profits and cash as a result of a presentation, I think we have done a good job." My good friend Gene Tyndall of Tompkins International also weighed in. In the 1990s, he famously led the supply chain business for accounting firm E&Y before that era came to an end. But he is well versed in accounting and the supply chain. "The models and examples you referred to are meaningful," Tyndall wrote. "However, in my experience (coming from E&Y), and talking actively with CFOs and accounting managers over the years, "keep it simple" is the best place to start." He suggests that might be with the six supply chain "mega processes": plan, buy, make, move, distribute, and sell. Then connect those with the four keys "flows": products, information, cash, and work. "If finance and accounting managers can learn all these basics, they can then participate better in supply chain strategies and operations," Tyndall says. "All too often, the terminologies used by either profession are misunderstood or misdirected. Once F&A and supply chain managers start collaborating, some important things can happen for the company and its customers." Peter Malone of PCM has done a lot in this area, and he says "I have learned that finance folks are often attracted to discussions related to supply chain ‘simplicity' and resulting cost savings potential - especially if they believe it possible to make bottom line impact without spending lots of money." Very often, he says, "supply chains have at least some historic component that results in complexity, inefficiency or waste of some kind, and this can become locked into the supply chain value map without a business realizing it (a bit like 'boiling a frog' as the old saying goes!)." Finance managers are very interested if you can show that that by getting back to supply chain basics, "it is often possible to strip out unnecessary complexity or to make simplifications that result in lower costs, smoother communications, reduced inventories, improved material and cash flow processes that result in overall improved delivery service, as a supply chain is more optimized." In effect, he says, "by challenging a company's "supply chain norm" at a basic level, there can be surprising yet simple improvements that result in improved competitiveness." Good stuff. There were quite a few more, but I am out of room. If we get enough feedback from today's column, maybe I can write a part 2! Any reaction these readers comments on accounting and the supply chain? Let us know your thoughts at the Feedback button below. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

YOUR FEEDBACK

We received several emails from last week's column on "Supply Chain Predictions 2015 from the Analyst Community, some of which we publish below.

Feedback on Supply Chain Predictions 2015 from the Analyst Community:

I agree with Gartner’s prediction that companies will get more disciplined about demand planning which will likely lead to the creation of more chartered demand planning organizations. Best practice companies have had such organizations for year but more companies are starting to realize that they need a longer horizon demand plan.

John Bermudez Infor |

||

| More on Supply Chain Predictions 2015 from the Analyst Community: | ||

Good article. In the past year, I have done webinars, blog posts, and presentation on a “Demand Management” organization and that companies need a Chief Demand Management Officer.

Traditional S&OP or IBP processes have been constrained by politics and lack of day to day analytics. That’s changing with Web 3.0 and the development of new tools

As always, you are providing great insights to the supply chain community.

Richard J Sherman

|

||

Fantastic job summarizing predictions from these analysysts. I know how hard it is to do what you do wit things like this, and you make it look easy.

Will 50% of supply chain executives be gone by 2018? Could be - executive turnover is rising at every position, and that has to include supply chain.

But I do agree the future supply chain leader will be much different from today's model, and that many current CSCO's will not be able to adjust.

How many will see the need to do make those adjustments - and how many will not really be able t look in the mirror and seen the reality of what needs to change?

Dennis Wilson Huntington, AL

|

SUPPLY CHAIN TRIVIA ANSWER

Q: How much have US truckload rates risen since the bottom in rates in early 2010?

A: Roughly 25%, according to the Cass Linehaul Index, which measures per mile rates. The index fell to a low of 100.5 in February 2010 (Jan. 2005 = 100), and ended December at a level of 126.4. The climb over that period has been very steady.

| © SupplyChainDigest™ 2003-2015. All Rights Reserved. SupplyChainDigest PO Box 714 Springboro, Ohio 45066 |

POWERED BY: XDIMENSION

|

"Current accounting practices, which have been around for decades, are not keeping up with the changes in supply chain," Denholm says.

"Current accounting practices, which have been around for decades, are not keeping up with the changes in supply chain," Denholm says.