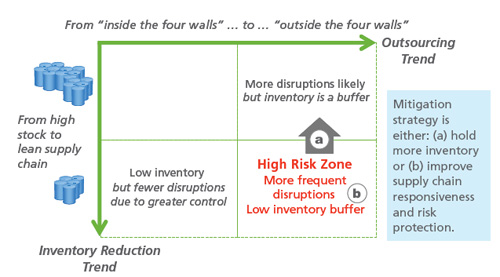

As shown in the graphic below, when these two vectors are combined (highly lean, highly virtual), supply chains are at maximum risk.

Source: Marsh Risk Management Practice

While most companies understand they need to make improvement in risk management strategies, it was still surprising to find not a single participant reported that their company was highly effective at supply chain risk management. The primary factors in this assessment (from corporate risk managers) are the lack of adequate staffing and challenges integrating well with the supply chain organization.

Insurable and Uninsurable Risks

Coming from an insurance company, it shouldn’t be surprising that a part of the report deals with this aspect of risk mitigation, but we actually liked the simple framework for categorizing supply chain risks.

Such risks are either insurable or uninsurable. For insurable risks, each risk can then be categorized as being currently insured or not insured. For uninsurable risks, each risk can be categorized as mitigated (formal plans/back up strategies in place) or unmitigated.

The real question then becomes the percentage of supply chain risk currently in each category, and whether that current risk profile should change.

Survey respondents believe that on average today, only 25% of his or her company’s end-to-end supply chain is being assessed annually for risk likelihood and impact.

“A lack of staff time and resources—combined with the complexity of supply chain processes that can involve thousands of internal and external organizations—create daunting challenges,” to such comprehensive assessments, the report notes.

The study concludes with these recommendations:

- Create a cross-functional supply chain risk team that looks end-to-end at the issues: Look harder at external risks, and make sure execs are reading the reports and supporting the efforts.

- Embed risk management activities and responsibilities into existing supply chain processes and functions and create consistency across the organization: Establish a center of risk excellence to provide templates and tools to create process consistency across the company, and make risk mitigation part of job descriptions and MBOs.

- Build up analytics and risk metrics: Increase the visibility to risks with web tools and create the ability to roll up data by country, supplier, product, etc.

- Extend the risk manager role: More integration between corporate risk management and supply chain decisions.

On the last point, often the risk manager comes up through the finance organization, but in some cases SCDigest is seeing the risk function being managed through the supply chain group. While this paper provides some very good insight, just how risk management and supply chain need to integrate is something that is probably worth additional research.

What’s your take on the current status of supply chain risk management? Is this a financial responsibility or a supply chain one? What strategies have you found successful? Let us know your thoughts at the Feedback button below.

|