There are a number of anecdotal stories of late on companies bulking up on inventory levels to buffer against significant delays in freight transporation, supply issues and other risks.

While far from all companies have taken that path, the numbers indicate changing inventory strategies in aggregate. Companies in the S&P 500, excluding sectors that have few physical inventories such as banking or software firms, increased their inventories by an average of 15% in Q2 versus the comparable period in 2019, according to S&P Global Market Intelligence. Those inventories were also 53% higher than the 10-year pre-Covid quarterly average.

Obviously, such inventory policy changes require more working capital to be tide up in that inventory. But there are other impacts as well.

Supply Chain Digest Says... |

|

|

In 2009, SCDigest published an article on how increasing warehouse space utilization starts to have a negative impact on operational efficiency. We thought it was worth a fresh look here in 2021.

As every distribution center manager knows, overcrowding in the DC can increase cost and cause many operational headaches. Crowded, unorganized areas become “black holes” for missing products. Crowded areas also cause increased damage to product that is often disposed of without inventory corrections being made. High-density storage makes it very difficult to accurately count the product. All of which and more leads to inventory accuracy issues and higher operating cost.

However, what may not be so obvious is the effect that shrinking storage space has on labor productivity. But, if your productivity is showing signs of decline while space is getting tight, it may be time to illustrate to upper management how tightly these two variables can correlate. In fact, small increases in space utilization above a “tipping point” can often lead to much steeper declines in productivity.

The simple key to understanding this relationship is keeping track of both productivity and space utilization over time.

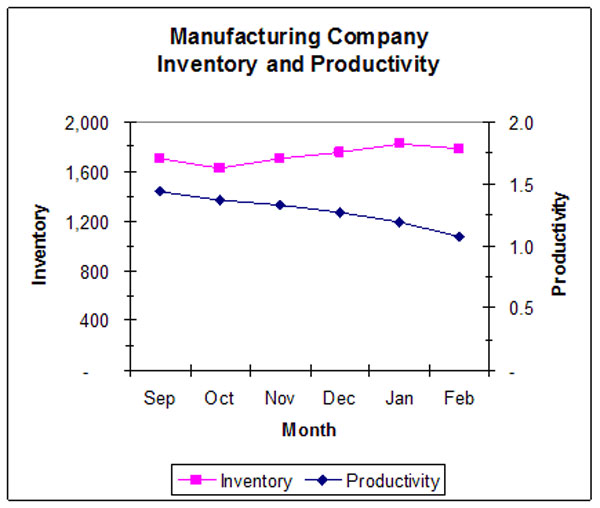

An example of how this data can be used is shown in the graphic below, provided to SCDigest by Fred Kimball of Distribution Design, Inc. Based on actual data from a manufacturing company with a warehouse that supports manufacturing materials as well as finished goods for customers, it clearly shows how productivity declined as inventory grew and space got tighter.

In this graphic:

“Inventory” was measured as pallets on hand at the end of each month.

(See More Below)

|

CATEGORY SPONSOR: SOFTEON |

|

|

| |

|

|

Productivity” was calculated as lines shipped per person per hour. This was the gross productivity measurement for the DC calculated by “all of the work” divided by “all of the labor” (including temporary and overtime). Productivity was expressed using this metric since all of the work supporting manufacturing, receiving, putaway, etc., was needed prior to shipping a customer order. This is also why the lines shipped per hour was in the low single digits; there were many tasks done by distribution personnel in this operation that are uncommon to many distribution centers.

In this specific example, it is clear that as inventory increased during the period, productivity declined, and at an accelerated rate. While inventory increased by 7% at the peak in an already crowded warehouse, productivity declined much faster, by 26%.

Kimball says that when it gets to the point that pallets are being staged in aisles, it is common that a lift truck operator might have to move as many as three pallets to get to the one that is needed. Then, the operator has to set down the needed pallet and move the three pallets back before picking up the needed pallet again. Instead of one touch to get the pallet, there are as many as seven touches, and the aisle is blocked to other lift trucks as this is happening.

On the other hand, when there is still ample storage space available at peak inventory, the productivity should not decline, at least not due to space getting tighter.

While recognizing that every facility is different, and the dynamic nature of distribution has an ever-changing mix of variables, the premise is clear that if a facility lacks sufficient space for peak needs and inventory grows, productivity will decline.

This then begs an interesting question: when, if ever, is it more cost effective to utilize outside storage to reduce over-capacity and increase productivity?

Companies that keep track of the relationship between storage utilization and productivity rates should be able to not only show management what the true costs of stuffing the DC with pallets are, but also how the DC additional costs might be balanced against outside storage costs.

Do you track space utilization versus DC productivity? At what level do you start to see productivity start to be negatively impacted? How do you determine when outside storage makes economic sense? Let us know your thoughts at the Feedback button section below.

|