| |

|

|

| |

|

|

|

|

|

| |

- Sept. 16, 2010 - |

|

| |

|

| |

To Make Optimal Sourcing Decisions in Consumer Goods, Companies Must Combine Detailed Data Across Many Areas |

|

| |

|

| |

|

| |

There is a lot of supply chain network design and optimization work going on right now, especially in the consumer products industry.

To do that job right, best manage trade-offs, and ultimately make the optimal decisions about what products should be made where requires detailed manufacturing cost data - which isn't always easy to achieve.

So said Dr. Mike Watson of IBM this week in a Videocast on The Supply Chain Television Channel. (The full Videocast is now available on-demand:Capitalizing on Supply Chain Complexity and Your ERP Investment in the Consumer Products Industry.)

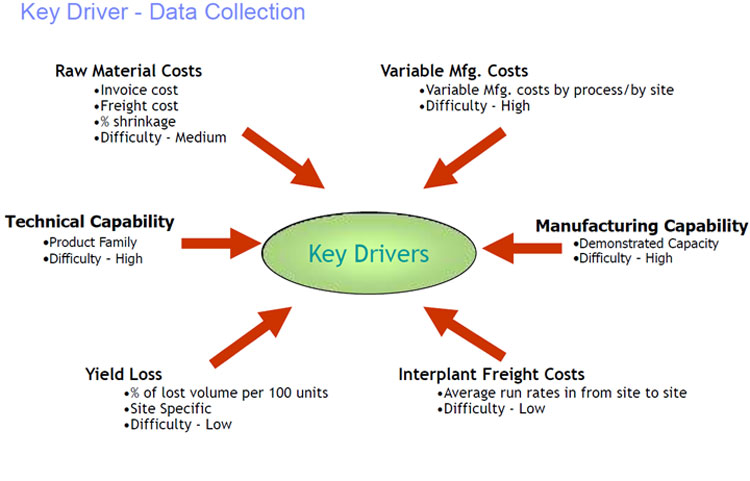

The graphic below from Dr. Watson shows the cost and capability buckets companies need to be able to understand in detail to get the most out of the optimal sourcing analysis.

Source: IBM ILOG

As can be seen from the chart, Watson say there are three areas where getting quality detailed information is especially difficult:

- True variable manufacturing costs by process

- The true technical capabiltiies of each plant by product line

- The true capacities of each plant by product family

Agree or

disagree? What is your perspective? Let

us know your thoughts at the Feedback button

below.

|

|

| |

|

|

|

| |

|

|

| |