What can companies do to reduce their fuel consumption in logistics?

We liked the framework recently announced by the consultants at the McKinsey Quarterly in a new interactive tool.

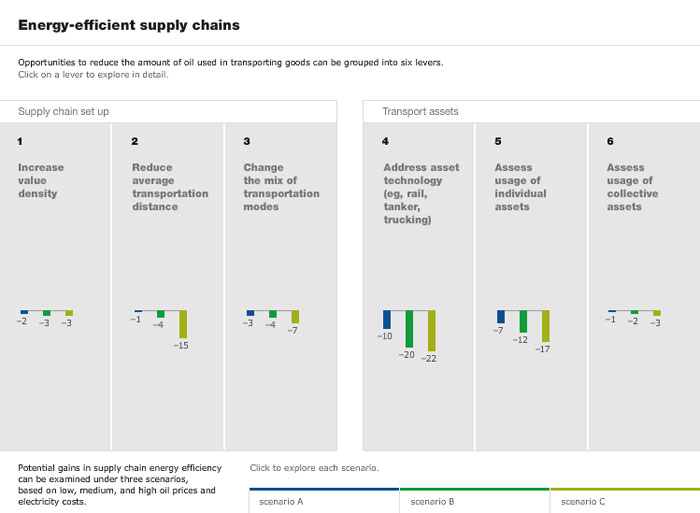

As shown in the graphic below, the McKinsey tool identifies six different levers for companies to reduce fuel consumption:

- Increased value density (e.g., concentrated detergent)

- Reducing average transport distance (e.g., improved network design)

- Changing the modal mix (e.g., truck to rail)

- Asset technology improvements (e.g., improving average truck fuel efficiency)

- Improving fuel efficiency of individual assets (e.g., improved routing)

- Improvements in collective assets (e.g., reduction in highway congestion)

We cannot do justice to the full insight in the interactive tool, which is available at the McKinsey Quarterly web site (see McKinsey interactive fuel reduction tool), but below we publish the summary graphic showing these six levers.

The three sets of numbers under each lever represents potential reduction in fuel usage based on different scenarios for future oil prices, though frankly this portion of the tool is a bit confusing. Still, the overall framework, and most of the insight, is quite interesting.

Source: McKinsey Quarterly

In looking at this framework, we would have added one more, something to do with collaboration or asset pooling, referring to approaches that reduce "deadheading" or involve different companies sharing transportation assets. It is implied in a couple of the McKinsey levers, but we think deserving of its own category.

Agree or

disagree? What is your perspective? Let

us know your thoughts at the Feedback button

below.

|