The choices in where to locate manufacturing capacity across the globe are growing increasingly complex. Costs are rising in China, companies it seems are now more reluctant to put too many eggs in the China basket, and other areas of the globe - from Russia to Brazil to the Middle East - offer growing markets in which Western companies might sell goods.

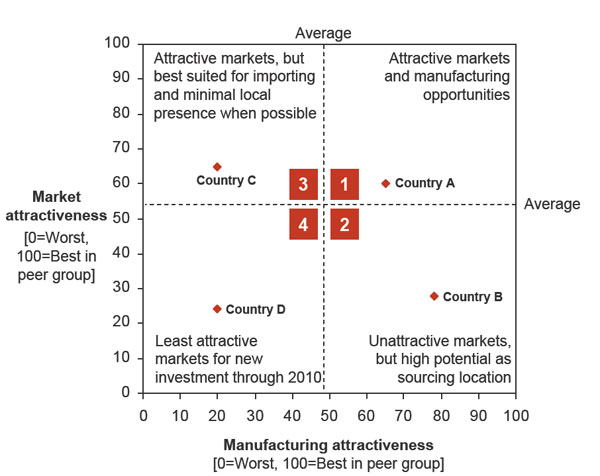

According to David Busch, a consultant at PRTM and former executive at contract manufacturer Solectron, companies should evaluate potential manufacturing offshoring options along two dimensions - manufacturing attractiveness (costs, supply base, logistics infrastructure, etc.) and local market attractiveness (size and growth of market, financial incentives, level of competition, etc.).

Busch presented the chart below at a meeting last week of the Medical Devices Supply Chain Council, held in Chicago.

Evaluating Offshore Manufacturing Options

Source: David Busch/PRTM

Performing this exercise across a number of potential locations will help companies to look rigorously and objectively at the options, and perhaps whittle a long list of potential countries/sites down to a smaller number that can be considered in even more detail. Busch said an often overlooked factor is the capabilities/availability of a local supply base for a given product category.

Agree or

disagree? What is your perspective? Let

us know your thoughts at the Feedback button

below.

|