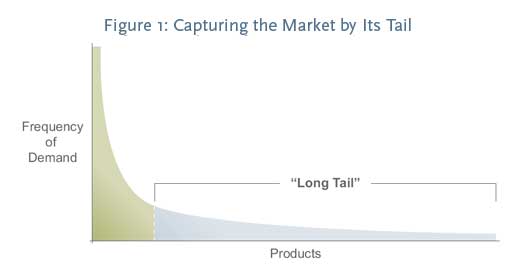

It's well understood that the Pareto Principle applies to most companies when it comes to inventory management and SKU counts; that is, approximately 80% of the demand and sales revenues come from just 20% of the total SKU base.

Most companies in theory would like to address this scenario by reducing SKU counts to focus the supply chain only on the faster moving products - not eliminating all of the bottom 80%, in most cases, but certainly a strong number of them, in the name of cost reduction and supply chain simplification. Analysis generally shows many of these slow moving SKUs lose money for a company.

In a recent book, "The Long Tail," author

Chris Anderson argued, instead, that these slow demand products can in fact lead to big profits by serving high profit niches.

Consultant group PRTM, which produced the Long Tail graphic below, argues that for many companies, the key to making profits with Long Tail products is frequently "modular design" and the use of Postponement strategies to minimize manufacturing and inventory costs.

"In order for modular design to deliver, it’s also important to have in place a postponement strategy where the final product is assembled close to the point and time of customer demand," PRTM writes.

"The conventional approach of manufacturing in large batches to leverage scale simply won’t work here—it creates too much excess and obsolete inventory," PRTM adds. "To meet the varied demand of small niches, you need to establish a supply base that facilitates customization."

Agree or disagree? What is your perspective? Let us know your thoughts at the Feedback buttom below.

|