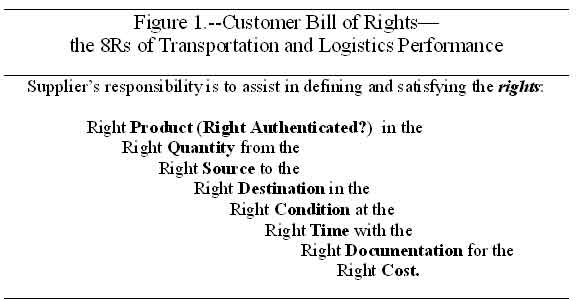

3. Right Source: Today sourcing policies by customers can be local, national and/or global depending upon the commodity. Customers are working with suppliers to help them determine the lowest “Total Cost of Ownerships (TCO)” when considering alternative supplier/sourcing locations. From a transportation perspective, many suppliers have multiple plants, distribution centers, and sourcing locations from which customers can work with suppliers in balancing transportation outbound and inbound lanes as well as continuous moves and consortium moves among collaborative buyers and sellers. The closest-distance, sourcing location may not be the lowest cost source! from right source as determined by buyer and/or seller? Routing of order/shipment considered when considering order/shipment planning procedures?

4. Right Destination: The customer may specify locations that are not ultimate point for sale or use. As firms work on consolidation among supplier locations, buyers may buy at the receiving dock of the “assembly” third-party provider. In other cases, buyers want their product not only delivered to the right facility in a complex of facilities at a certain location but also delivered at a point of use, point of sale, or even at a point of installation in which the supplier has its employees positioned to install or setup a product for use. Product destined to correct consignor location for receipting, inspection, use or sales? Inside delivery and installation/stocking required by buyer? Does “diversion—legal or illegal” occur for this organization in specified industry(s)?

5. Right Condition: Customers want their products ready for use or sale with no loss or damage, no moisture, no overages with the right identification, such as bar coding or RFID tags on cases and pallets. As stated above, the customers want the right pallet configurations or right returnable containers to provide quick acceptance and positioning of the product for use or sale. Is shipment delivered as meeting buyer’s performance requirements as to use or cross-docking or quick transfer to floor sale or use? Specific bar coding, RFID, other AIDC technologies plus other packaging/unitization required? Product received without OS&D?

6. Right Time: In today’s environment of Just-In-Time, the right time must be set by buyer, seller, and transportation/logistics services providers to meet the schedules of use or sale. Guaranteed freight delivery times have become very prevalent. However, not item needs to be delivered as fast as possible. Many customers want weekly delivery schedules to meet restocking or usage needs. These are the low cost solutions that users, buyers, sellers and providers must determine cooperatively. Many customers are sharing more schedules and ultimate sale and use of products so providers are not blind sided with not knowing what is really going on the front lines. Timing is crucial timing of order/shipment as order progresses from need conception to point of use or sale tracked for compliance? Pick-up and Delivery times established on Time-Definite requirements? Order/shipment meet milestones and end delivery requirements? Product delayed because of any security breaches or required government or business inspection.

7. Right Documentation: With the demanding Rights above, documenting and communicating clean, reliable information is crucial among parties. In addition, today’s security requirements ensuring that information is not getting into the wrong hands or to meet government requirements requires that all parties cooperate in making sure that perfect information is passed among parties securely. If bad or unreliable information is passed along initially, then imperfect shipments are realized. The quality of transportation and logistics fulfillment is necessarily tied to the obtaining of perfect information. This has led firms to begin to specify “perfect orders” separate from “perfect shipments.” Perfect orders relates to getting all of the performance specifications agreed upon before the shipment is prepared and tendered to T&L providers. are all required documents—paper or electronic—prepared and correctly filled out to satisfy business and regulatory requirements? Is payment for goods received with proper documentation and instructions as goods are turned over to buyer from seller? ASNs communicated on a timely basis?

8. Right Cost: All of the above Rights lead to the point that transportation charges/prices are only part of the Cost formula. Lowest Delivered cost when considering product costs, order and shipment documentation preparation, possible inspections, and transportation from initial origin to ultimate destination between buyers and sellers goes beyond “price.” When considering the costs of in-transit, stationary, and safety inventories, TCO as mentioned above must be considered. Ultimately, so-called “supply chain economics” necessitates that inter-enterprise, cross-functional costs be considered that cut across suppliers, intermediaries and buyers in more complex, strategic sourcing decisions and operations. Are right charges assessed for order shipment including product costs, trade discounts and allowances? Any special damages assessed if guarantees of deliveries not met? Consequential damages for lost sales or shut down production/operations assessed when sellers, carriers/LSPs and receivers put on notice for specified areas of performance? Right cost is indicated instead of Right Price because total costs go beyond cost of goods or merchandise to include ancillary charges leading to Delivered Cost and when inventory and other procurement and logistics costs are considered, the Total Costs of Ownership is target consideration.