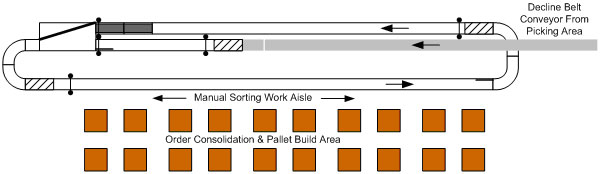

The Low End - The Poor Man's Sorter: One low cost approach to sortation is to implement what SCDigest refers to as a "poor man's sorter," in which batch picking strategies are employed to reduce labor costs, but rather than automatic sortation, but a simple re-circulating loop off which operators pick cartons to pallets (see graphic below, and read Sorting Completed Picks for the Smaller DC

The Poor Man's Sorter

Source: Supply Chain Digest and Distribution Digest

Don't let the name fool you. This can be a very effective approach for companies that do not have enough volume (more than 10,000 or so cartons per day) to justify a fully automated sorter, and has in fact been used by many large companies in some operations.

Cost range: $250,000 to $350,000, including pick modules

Basic Automated Sortation System: Capable of handling some 20,000 cases per shift, a basic system would have conveyors from existing full case pick areas to lower

speed pop-up wheel sorter with 12-15 diverts.

Cost range: $750,000 to $1.5 million

Medium Throughput System: Capable of handling perhaps 40,000 cartons per shift, this level system might include 2 two-level full case pick-to-belt modules; an automated print and apply labeling system, some split case picking support. and use a medium-speed shoe sorter with 12-15 divert lanes.

Cost range: $2-4 million

High Throughput System: Capable of handling perhaps 60,000 cases per shift, the high end system might include 3-4 two-level full case pick-to-belt modules or 2 three or four-level full case pick-to-belt modules, split case

pick modules; automated label print and apply systems, and use a high speed

shoe sorter with 24-48 diverts.

Cost range: $6-10 million

At mega-distribution centers found in large retailers some other operations, even higher end systems are often needed, with costs esclating proportionately.

There are many variables, and while the ranges provided are fairly broad, they at least give logistics managers some guidance as to what a sortation system for their operations might cost, and provide a range for some initial assessment about potential ROI and capital budgeting requirements.

Is this type of cost information helpful? Do our cost estimates square up with your experience? Let us know at the Feedback button below.

SCDigest is Twittering!

Follow us now at https://twitter.com/scdigest |