Cliff Holste, Materials Handling Editor Cliff Holste, Materials Handling Editor

| |

SCDigest Says: |

| |

The larger message here is the need for logistics managers and executives to do a lot more “management by walking around,” and to have a bit more faith in the “wisdom of the troops.. The larger message here is the need for logistics managers and executives to do a lot more “management by walking around,” and to have a bit more faith in the “wisdom of the troops..

Click Here to See Reader Feedback

|

CBS has a small hit on its hands with its “Undercover Boss” series, in which corporate CEOs disguise themselves and go work among the troops across a wide variety of companies and industries.

If you missed it, in late March one of those executives was Michael Rubin, CEO of the billion dollar e-commerce giant GSI Commerce, which does outsourced e-commerce development and order fulfillment for dozens of leading e-tailers and consumer brands.

As with other CEOs, Rubin disguises his look, changes his name to "Gary Rogers," and then spends time in both the company’s major distribution center in Richwood, KY as well as a call center in Florida.

The set up isn’t totally disguised, as “Gary” is supposedly doing some research for a documentary on seasonal work, but the workers and supervisors certainly do not know it is the company’s own founder and CEO.

The full program can be viewed here: Undercover Boss GSI Commerce. We summarize details in text and pictures below.

Rubin decides to do this during the company’s peak Christmas fulfillment season, when order volumes increase by as much as six times over other periods. Volumes at the Richwood DC soar to as many as 75,000 cartons per day, virtually all “pick and pack” business. It’s also a time when GSI’s use of temporary workers soars, and Rubin realizes that he has had “little exposure to our seasonal employees. This is a great opportunity to go into the company as a seasonal employee and see the job through their eyes.”

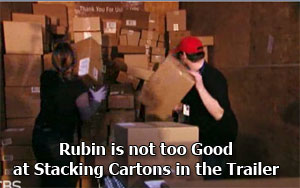

He is first assigned to truck loading, where packed cartons are loaded into an empty trailer for parcel shipment. He is first assigned to truck loading, where packed cartons are loaded into an empty trailer for parcel shipment.

His work partner, another temporary employee who has been there just three weeks, lets him know right away that “We want it high and tight. All the way up, floor to ceiling.”

“Rashelle” recommends loading boxes of the same size in columns at the back of the trailer, and building a pattern forward.

But Rubin is not very good. Boxes keep coming and coming.

“They don’t stop,” Rubin later notes.

One thing he quickly learns: distribution center jobs are tough. He is extremely tired within the first hour, and exhausted by the end of the day. Boxes on his side of the trailer look horrible, and continue to fall to the ground. At one point, he swings around with the box and smacks Rashelle hard right in the face with it.

“For the first time in my career, I wish orders would stop coming,” Rubin says. “I was embarrassed that I couldn’t keep up, the job was so hard.”

On to the Call Center before Back to the DC

Rubin next moves on to the GSI call center, where is placed into the “escalation” area, where customers who can’t be satisfied by front line customer service reps are transferred for additional handling.

It’s an eye opener. First is the recognition of the sheer scale of the different customer problems that must be solved – and with a relative lack of clarity on how to resolve them.

Many of the customer issues in fact relate to logistics. Many of the customer issues in fact relate to logistics.

“The main thing we do here is apologize,” his first escalation trainer tells him.

“I have one thing to say - we opened the box and the item was crushed,” one customer is heard saying.

“Why would it take until day of shipment to notify me?” asks another.

He soon finds some system issues. A customer is entitled to a $50.00 credit on an item being purchased, but GSI’s order management system cannot just deduct the credit from the purchase price. The customer has to pay full price, and then get the credit back a few days later – and she is not happy about it. (See new white paper on Next Generation Order Management.)

Rubin himself tries to deal with the customer for awhile – but doesn’t do very well, and clearly doesn’t have any real idea what his moves should be.

“She is overpowering you right now,” a new trainer tells Rubin after putting the customer on hold. She takes back control of the call, and in the end, the CS rep gives the customer a number to “call corporate.”

Rubin would like to fire the CSR on the spot, but can’t. (Distribution Article - Continued Below)

|