Data Needed for Order Picking System Design

According to Cliff Holste, SCDigest’s Material Handling System Editor, to determine order picking strategies and technologies, companies need to obtain and analyze the following types of data:

- Order mix distribution (family mix, handling unit, order increment);

- Lines per order distribution;

- Cube per order distribution; and

- Lines and cube per order distribution.

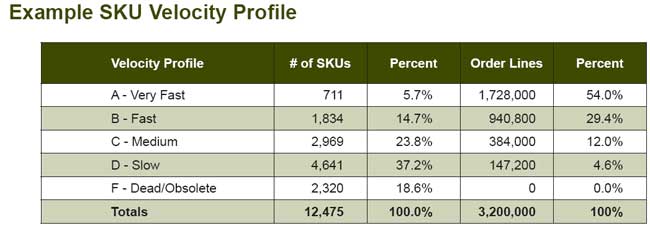

Analysis should, in part, develop a SKU velocity profile, similar to the chart below.

The analysis will then also typically involve breaking this data down into movement volumes by different handling/picking units, such as full pallet, full case and split case activity.

The next step is an iterative process, and is constrained by many factors, especially if the analysis is for an existing building rather than a “green field site.” It may also be that a company wants to look only at one area, such as piece picking.

A comprehensive analysis will include both analyzing at where some group of products (such as the “Very Fast” full case movers) will be stored, in what type of storage mode (e.g., double deep pallet flow rack, half pallet, etc.) and what picking strategy/technology will be used (voice or RF pick to truck, pick by label, voice or RF pick-to-belt, pick-to-light, etc.).

The analysis can get very sophisticated; for example, in some businesses it makes sense to look at items that are almost always ordered as single line items, and store those in a separate area of the DC. It can also pay to look at SKU/Order relationships – a relatively slow moving SKU might make sense to store in the high-velocity area, if when it is ordered, it almost always is ordered with a Category A product.

The key points:

- Order picking systems decisions are closely tied to location and storage mode decisions;

- Different order picking technologies are best suited to SKU velocity profiles for a given unit of measure; and

- Different order picking technology investments will have different ROI depending on the level of activity within a pick zone. SKU and order activity profiling is essential to optimizing these decisions.

“You should probably do SKU and activity profiling at least annually even in “normal” times,” says Holste. “Coming out of this recession and unprecedented changes in consumer demand and how specific DCs operate, it is especially critical right now.

Is SKU and Order Profiling analysis needed by most companies right now? What are some smart practices for doing it well? Let us know your thoughts at the Feedback button below.

SCDigest is Twittering!

Follow us now at https://twitter.com/scdigest |