S&OP is Important – but not Enough

A growing number of companies place a high level of importance on the Sales and Operations Planning (S&OP) process, and rightly view S&OP excellence as an important component of integrated planning and execution.

S&OP excellence is essential to integrated planning and execution, but, by itself is not enough. S&OP helps align the organization, perhaps even superbly, across a set of objectives and a common forecast, but S&OP alone will not get companies to the “Sense and Respond” supply chains that will ultimately define supply chain leadership and true integration of planning and execution.

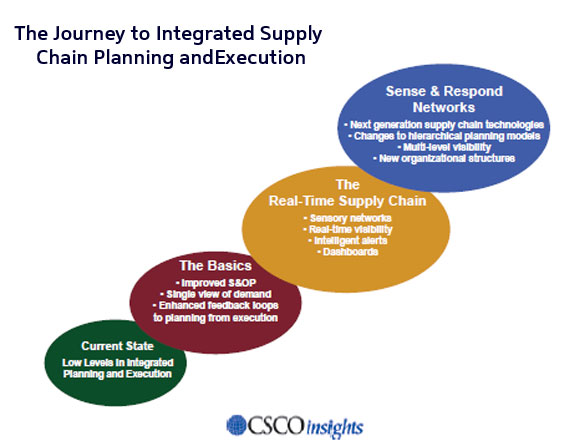

We see four levels in this journey:

- Baseline State: Mediocre sales and operations planning processes; planning and execution processes that are disconnected and operate largely in silos;

- Phase I - The Basics: Improved S&OP, a single view of demand, and enhanced feedback loops to planning from execution;

- Phase II – The Real-Time Supply Chain: Sensory networks, real-time visibility, intelligentalerts, and decision-support dashboards; and,

- Phase III - Sense & Respond Networks: Next generation supply chain technologies, changes to hierarchical planning models, multi-level visibility, and new organizational structures.

As one survey respondent noted, “You have hit on a very good topic here. Better integration of planning/execution will be the next big trend.”

We believe it is even more than that. For a period of time, those companies that can well integrate planning and execution will enjoy competitive advantage and superior operational and bottom-line results. Soon, achieving a high level of integration between supply chain planning and execution will move to become a competitive necessity.

Ultimately, companies will significantly redesign existing processes and organizational structures to fully realize the opportunities that a sense and respond supply chain can deliver.

As never before, technology and information flow will be needed to power this transformation. Multi-level supply chain visibility, a synchronized view of demand, robust analytic tools to support enterprise S&OP, continuous use of network planning and optimization tools, supply chain dashboards – these are among the technology-enabled capabilities that will be deeply intertwined with the new integrated planning and execution paradigm.

We are excited about this analysis and the journey that lies before us all.

It’s time to get started.

Do you think we still have a long way to go to get to high levels of integrated planning and execution, or not? What do you see as the key organizational, process, and technology barriers? Let us know your thoughts at the Feedback button below.

SCDigest is Twittering!

Follow us now at https://twitter.com/scdigest |