Clearly, RFID tag-reader performance continues to improve across many attributes, especially in the ability to work with tough materials such as metal, but there can still be significant differences in how well different tags following the same base standards will perform in specific applications.

That’s part of the message from a recent report from the European EPC Competence Center (EECC), according to the center’s manager Conrad von Bonin.

Earlier this year, the center ran substantial tests on some 30 different tags from a variety of manufacturers, as they have done in previous years.

One noticeable finding – tag performance on tough-to-read metal surfaces is improving, and the goal of having one tag that can go across metal and other surfaces effectively has probably arrived.

“All ten specialised UHF transponders produced metal tagging read ranges of 4 to 10 metres, which debunks the myth that RFID is unsuited for metal environments,” von Bonin said. He added that some tested metal transponders are designed specially to work regardless of the material being tagged. This enables effective tagging of liquid containers, as well.

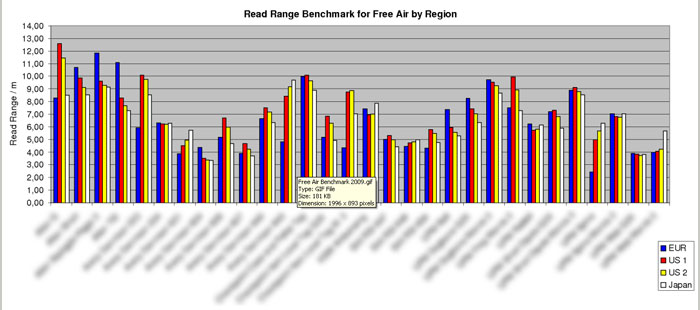

The EECC has developed a detailed methodology that allows it to calculate what will be the actual tag read range in operational environments. The read range of transponders is the most important criterion in determining whether RFID can be used for a particular application, von Bonin says.

(See chart below, showing the read range estimates by different tag manufacturers and frequencies, based on the EECC testing method; the specific tag names are greyed out, as the EECC sells this report.)

(RFID and Automatic Identification Article - Continued Below)

|