The most obvious implication, says Wheeler, is that it usually becomes apparent that a “one size fits all” approach to wireless in distribution, where every worker in the DC uses the same equipment, or there is just a simple breakdown between hand helds and vehicle-mount terminals for fork trucks, may not really optimize productivity. Wheeler made his comments on a recent Supply Chain Videocast on Using Multi-Modal Wireless to Drive Productivity Gains in Distribution, now available On-Demand: Multi-Modal Wireless Videocast.

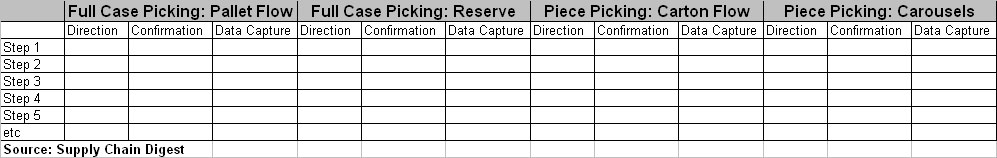

In the same broadcast, SCDigest editor Dan Gilmore noted that “You can’t even think about picking as one task type – you may have case picking, piece picking, etc., and even sub-types within each of those.” While it could be the same wireless technology mix will be optimal for each type, there may also be different needs.

A sample approach to this analysis is illustrated in the matrix above.

While such an analysis can take some time, the benefits will be worth the effort, Gilmore says.

“Doing this work will really help companies see the big picture about all the requirements they really have, which will often be more specific by task type than they realize,” he observes.

By putting this kind of analysis together, companies can better understand what would be optimal for each task, then as makes sense aggregate some of that intelligence to determine a manageable set of technology options.

In today’s environment, however, users should start by focusing on crafting a highly flexible platform, Wheeler notes.

“Today, you might not have to capture a lot of data, but next year maybe you do,” he said, noting coming requirements for intense traceability data capture in the produce and health care sectors.

What do you think? Let us know your thoughts at the Feedback button below.

SCDigest is Twittering!

Follow us now at https://twitter.com/scdigest |