While the full scope of MES solutions available today is quite broad, the reality is that most manufacturers have only adopted a fraction of those capabilities on the shop floor. Recently, many companies have been reluctant to invest in manufacturing capabilities because they have been uncertain as to whether the operations would be outsourced or not.

The Global Plant Floor Approach

IDC recommends a new, more strategic approach to shop floor technology-enablement. This “global plant floor” would operate like a “unique virtual factory that consolidates the number of different manufacturing plants in terms of resources, processes, and products,” the report says.

In addition to taking a more enterprise view of manufacturing plants and capabilities, this new global approach would address the following types of issues, according to Manufacturing Insights:

- Harmonization of global manufacturing operations — creating a uniform environment for all plants globally as a way to automate decision-making

- Manufacturing intelligence — gaining a higher visibility of global manufacturing operations as a way to gain more centrally managed control over manufacturing capabilities across multiple sites

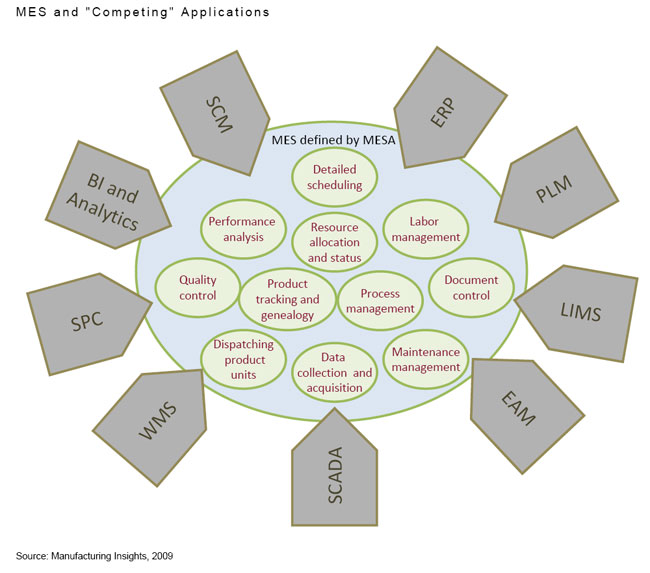

- Seamless integration with corporate business applications — intimate integration of manufacturing operations processes and data with corporate-wide ERP system and other applications

- Connecting design and manufacturing operations — empowering R&D efficiency and lowering documentation costs

- Improve fixed assets utilization — Advanced maintenance management as a way to increase plant availability, reduce operational costs, and minimize capital expenditures

- Compliance and environmental footprint reduction — reinforcing regulations and reduce manufacturing operations environmental footprint

“Existing MES systems, typically home grown or highly customized, are getting old and need a thorough rejuvenation,” the report says. Investments in the new generation of MES solutions, which in part will leverage the “internet of things” (i.e., sensors, actuators, identification chips, and GPS transmitters to wirelessly interconnect and provide for a “continuous reconfiguration of the plant floor to support current demand”), will be required for most manufacturers.

In the end, the global plant floor will be more virtual than physical and will be operated through interfaces that look much like a session on Second Life, the virtual reality world platform, Manufacturing Insights says.

The key point is that manufacturers need to take a more strategic and centralized view to shop floor operations and technology – “shop floor to top floor,” as the decades old saying goes.

Do manufacturers need a new generation of MES? Are they ready for it? Do you like the concept of the Global Plant Floor? Let us know your thoughts at the Feedback button below.

SCDigest is Twittering!

Follow us now at https://twitter.com/scdigest

|