Holste Says... |

|

| For many shippers real-time order processing is impacting on the way receiving, putaway, picking, packing, and shipping are executed. |

|

What do you say? |

|

| Click here to send us your comments |

|

|

|

- The Warehouse Control System (WCS) software monitors the flow of product thru the DCs handling system controlling when cases are released from accumulation lanes to the sorter. Any interruption in flow is reported immediately. The WCS is also monitoring sortation operations to determine where to send product, e.g., the shipping dock or may need to go to the product sequencer if building store ready pallet loads.

- A worker performs a put-away or stock move using a mobile handheld computer. The worker scans the bar-code label on the product and the system recommends the optimal put-away location. The worker can select that location, or override it and place it in another location. The worker scans the bar-code of the destination location to ensure that the item is placed in the correct location. The Warehouse Management System (WMS) is immediately updated as to the status of the goods in real-time, and even knows when goods are in transit being moved from one location to another.

- The WCS senses heavy volume at a particular shipping lane and calls for additional operators (via voice or RF terminals) to that lane to head off congestion and delays. Or, in a multi-line palletizing system, if a palletizing machine goes down, the WCS can automatically direct product to a backup palletizing line.

- The WMS allocates inventory and organizes picking waves at the beginning of the shift based on the orders that have been received into the system. But then, sometime well into the pick cycle, an order becomes a higher priority than was originally planned, or a new order that must be shipped today shows up. Sound familiar? No problem – with real-time order processing, the WMS can internally re-shuffle the remaining orders to accommodate the new or expedited order without interrupting other operations.

- In DCs where the number of active SKUs exceeds the number of available picking slots, real-time information can be used to manage a dynamic pick face strategy. In this example selected products are stored in a mini-load storage system to maximize cube storage space then delivered as needed to an open pick location. In this way, one picking location may be used for several products on an as needed basis.

In addition to improved warehouse slotting and inventory accuracy, real-time control makes it possible to quickly react to order processing and/or unexpected operational changes.

Managing Labor in Real-Time with a Warehouse Control System (WCS)

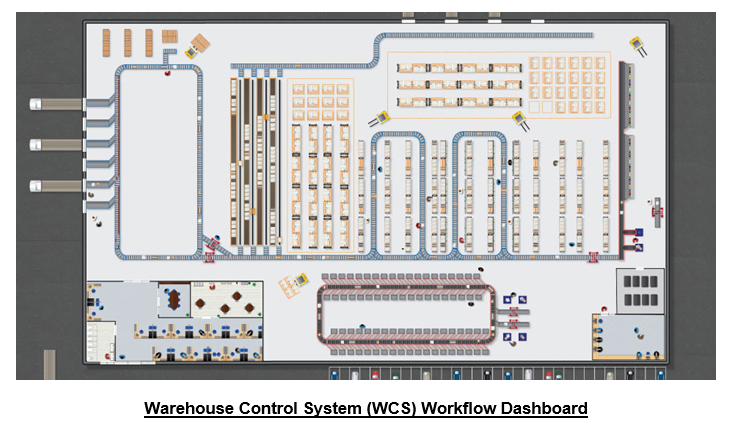

With the WCS technologies now available, managers get a workflow dashboard (similar to that shown above) that provides a visual representation of everything going on in the DC in real-time and by using the various dropdown menus, can easily make changes. Assuming workers have been cross-trained, real-time information can be used to optimize the workforce in the DC. For instance when plans change, as they often do, the WCS can quickly suggest a plan for reallocating the available labor based on the new demand. In this way labor management systems (LMS) and WCS work in tandem with voice and/or RF technologies to reallocate labor and tasks throughout the DC.

Real-time Control Extends Beyond the DC

Using point-of-sale (POS) technology, retail managers can see that they are about sold out of a specific SKU in one store, while there is a surplus in another store. Now instead of getting on the phone to manually arrange a stock transfer the transaction can be done quickly on-line.

For many retailers having access to up-to-the minute information about on-hand inventory and customers’ order shipping status is critical to managing their business. For example: did the cartons of snow shovels destined for Minnesota already ship, or can they be redirected to New York. In order to answer this type of inquiry the company must have real-time visibility into inventory, order fulfillment, shipping, and even billing.

Industry experts agree that the best way to do that is through a secure Enterprise Portal which is a specially designed website that serves as the single point of access for real-time information sharing, inventory visibility, notification and task management. This IT solution enables collaboration throughout the supply chain, giving customers the most accurate and timely view into the status of their orders. Customer can make knowledgeable decisions based on changing demand. So when the radar shows that the snowstorm has shifted to the northeast, they can access up-to-the-minute information to know whether they can re-direct those snow shovels to where the highest demand will be. For more information see: http://www.atlanticwebfitters.ca/AboutCMS/WhatisaWebPortal/tabid/95/Default.aspx

Likewise, with visibility into the contents of containers coming into port along with real-time inventory levels in DCs and stores, retailers can postpone the allocations of inventory on a cargo ship until it arrives at the DC receiving dock, then crossdock it to the store based on demand.

Final Thoughts

Increasingly, shippers and retailers are operating in a demand-driven quick response world. Upgrading to real-time control should be high on the priority list for every company that wants/needs up-to-the-minute control of operations.

Any reaction to this Expert Insight column? Send below.

Your Comments/Feedback

|