The price of oil and hence the cost for fuel such as diesel is one of the largest - and most variable - drivers today of total supply chain costs. Not only does the price of oil directly affecttransportation costs, but oil is the base source for a variety of products used to manufacture goods (plastic being the most obvious example).

In its annual review of world energy, BP as always included a wealth of facts and figures (See

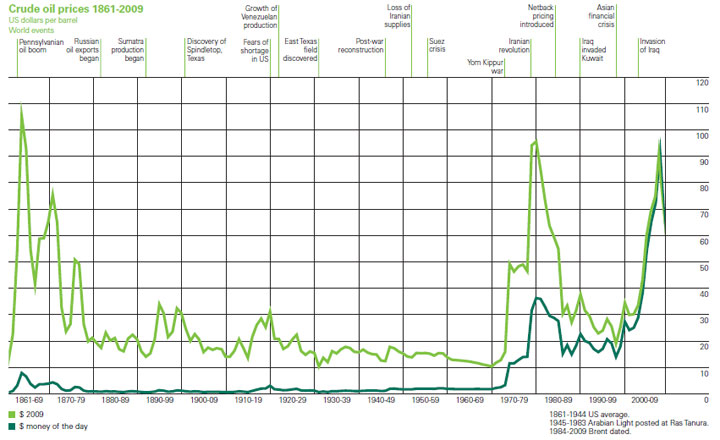

Summary of the Annual BP Statistical Review of World Energy). In that report was the following figure, which shows the price of oil from its first use about 140 years ago to 2009, both in actual dollars per barrel as well as constant dollars, using 2009 as the base.

Source: BP Statistical Review of World Energy

As can be seen, there have been three main periods of a relative spiking of oil prices. At the very start of the oil era in the 1860s, during the first and then second "oil crises" of the 1970s, and then again starting in 2003.

While oil prices have fallen back by more than half from their 2008 peaks, through the lens of history even at $70-80 dollars a barrel, where oil has been trading lately, it is still very expensive.

Agree or

disagree? What is your perspective? Let

us know your thoughts at the Feedback button

below

|