Inventory Optimization software can help companies answer the following types of questions:

- How much inventory should I hold of each product, and where is the most cost-efficient point to store that inventory?

- My products are often seasonal or cyclical in terms of demand — how do I most efficiently plan and deploy overall inventory?

- What business policies are driving inventory investment across the entire supply chain?

- If I must improve service, how much incremental inventory investment will I need? Conversely, if I decrease service level, how much inventory can I free up?

- How will a change in a supplier or production location impact my overall inventory cost or customer service levels?

- Can I increase margins and improve service by holding inventory in a different location?

- How can I best deploy a combination push-pull supply chain or an inventory risk-pooling model?

There are actually two different modes of planner interaction with Inventory Optimization tools.

In one mode, planners work directly with the system, and interact with the application to obtain inventory targets or perform analysis.

The other mode is more of a “manage by exception,” with most inventory recommendations or safety stock targets sent directly to the designated advanced planning system (APS). Planners are notified of potential issues or problems, which they deal with individually.

Moving Away from “Black Box”

Inventory Optimization technology has actually been around for a number of years, but, until recently, was very much a niche application that was viewed as primarily the province of operations research (OR) professionals.

That has started to change. Inventory Optimization solutions “are becoming more universally understood and accepted by business and supply chain planning professionals,” IDC says. That is, in part, because the user-friendliness of the applications has increased substantially over the past 2-3 years.

Part of that increased acceptance also comes from a generally compelling ROI potential. Manufacturing Insights says it is not unusual for a global supply chain to see inventory levels reduced by as much as 15–25%.

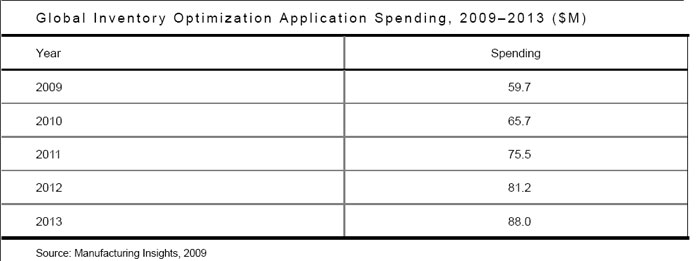

While the market for Inventory Optimization software is small compared to other segments, Manufacturing Insights expects it to grow rapidly over the next five years (see graphic below).

According to Manufacturing Insights’ Simon Ellis, “The key vendors in this [Inventory Optimization] space offer maturing applications with strong functional capability. If IO is not on your short list of priority projects, at least look at these applications as the level of benefit may surprise you!"

Ellis emphasizes that the majority of IO offerings in the current market have been built around unique algorithms and structure, which yield somewhat different approaches and results. In evaluating potential solutions, therefore, it is critical to consider how well an individual vendor's approach matches up with your specific supply chain and inventory management challenges.

Do you have experience with Inventory Optimization software? What are the pros and cons? What do companies need to consider in selecting and deploying these tools? Let us know your thoughts at the Feedback button below.

SCDigest is Twittering!

Follow us now at https://twitter.com/scdigest |