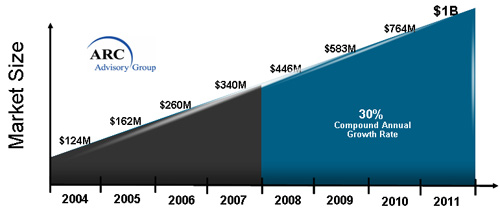

The chart below, taken from a recent ARC report on the topic, shows users are rapidly adopting Industrial Ethernet technology, with projected compound growth rates of 30% through 2012.

Industrial Ethernet Expected to Grab

Increasingly Large Share of the Market

Source: ARC Advisory Group Research Report

Traditional “device networks,” are not dead, however, said Forbes. This is still a growing market, just one that isn’t growing as fast as Industrial Ethernet.

“Alternative device networking technologies themselves now are largely “open” in the sense that they are shared technologies owned and managed by industrial consortiums rather than by single suppliers,” added Forbes. “These device networks continue to have installed cost advantages especially for the simplest industrial devices with limited potential for diagnostic information. Several such networks now combine Ethernet at the physical layer with other more “proprietary” or specialized technologies. The objective is to optimize performance of a particular function or machine, while keeping the advantages of Ethernet’s ubiquity and openness.”

Forbes adds that Industrial Ethernet’s migration to lower levels of the automation hierarchy will result in the traditional device network value proposition solidifying around installation cost savings and use in meeting application-specific requirements. Forbes adds that Industrial Ethernet’s migration to lower levels of the automation hierarchy will result in the traditional device network value proposition solidifying around installation cost savings and use in meeting application-specific requirements.

The reality is that for some time companies will likely still embrace multiple networking technologies on the factory floor.

“More companies need to develop the concept of a managed portfolio of equipment and technologies that they deploy across their operations, along with strategies to exploit them,” Forbes said. “The larger manufacturers have done this for decades, but they are always refining their process for doing it. The advantages they are pursuing now come from improved asset management and utilization, more flexible and visible operations, higher product quality, and more collaborative asset management and maintenance.”

Cisco Releases New Industrial Ethernet Switch with “Hot Swap” Capabilities

On a related note, networking giant Cisco, which is looking to aggressively expand its presence on the factory floor, announced in late 2007 a new family of Industrial Ethernet 3000 switches, expected to be available at the end of the second quarter of this year.

The new switch family, and extension of the company’s previous line of Industrial Ethernet switches, adds a number of new security, networking and durability enhancements to its previous models. Security has emerged as a key issue in open Ethernet-based networks, which could be vulnerable to hackers or others if the right security layers are not implemented in factory networks.

The 3000 family utilizes Cisco’s proven security approach in use in switches and routers deployed by the company for other enterprise applications in thousands of enterprises across the globe.

Perhaps the most interesting new feature of the 3000 family, however, is the ability to store a switch’s configuration, and then quickly swap that information into a replacement switch in the case of a hardware failure.

The switch operating system, device specific configuration, and other data are stored on a flash drive that Cisco calls its “SwapDrive.” If a switch requires replacement, general maintenance personnel can replace the switch and then easily add the SwapDrive, and the new switch is immediately up and running without IT support.

ARC’s Forbes agrees this is a valuable innovation: “The Industrial Ethernet Series 3000 represents a new and truly industrial product for Cisco, as opposed to hardened enterprise switches,’ Forbes said. “Equipment modularity and embedded IEEE 1588 are new aspects, but more important is the new capability for hardware replacement without IT involvement. This will allow personnel without Cisco networking expertise to support these switches in critical environments.”

Is “Industrial Ethernet” poised to dominate the factory floor networking environment? Why or why not? Let us know your thoughts at the Feedback button below. |