|

By Jack Horst

Kurt Salmon Associates

The pace of change in supply chain, especially for retailers, has been incredible. We’ve had 50 years or more of progress crammed into 15!

It was not that long ago that most companies:

- Sourced domestically

- Mailed their POs

- Touched everything, multiple times

- Shipped from “one size fits all” DCs and networks

| Horst Says: |

50 years or more of change crammed into 15. We’re now operating in “dog years,” with rapid time compression versus what we have been used to. 50 years or more of change crammed into 15. We’re now operating in “dog years,” with rapid time compression versus what we have been used to.

What do you say? Send us your comments here |

In the past 15 years, all that has changed dramatically. Vendors no longer call all the shots, as retailers have defined service requirements supporting:

- Pre-allocation and merchant pre-distribution

- Cross-dock processing speeding merchandise to store floors

- Multi-channel processing supporting evolving business strategies

50 years or more of change crammed into 15. We’re now operating in “dog years,” with rapid time compression versus what we have been used to. Do any of us think the pace of change is likely to slow? A resounding NO!

Even the very best, most visionary retailers must feel a little like George Jetson, who spent his life trying to keep up with his “best friend” Astro, who was always just a step faster on that treadmill.

How do you turn up the speed on your own treadmill to accelerate your supply chain performance onto a “dog years” trajectory?

In this 4-part series, we’ll explore the kind of visionary and game changing collaboration the very best retailers and their suppliers and service providers are delivering to continuously accelerate the pace of performance improvement.

“Acting Vertically” to Drive Performance

Einstein had his E=mc2, a shockingly simple equation explaining the mysteries of the universe.

Exhaustive research KSA has conducted of over 100 leading retailers reveals that winners in today’s increasingly competitive market harness a similarly simple concept that leverages the retail equivalent of Einstein’s historic construct.

We call it “Act Vertical,” and it describes a new retail world in which success is defined by the speed with which brand “right” merchandise is made available to customers through energized retail experiences.

Act Vertical retailers are “unifying” their operations, collaborating internally across what previously were functional silos, and also externally with vendors and other service providers. As a result, they can replicate the efficiency and responsiveness of supply chains in which one company controls all aspects of merchandising, product development & sourcing, logistics and store operations.

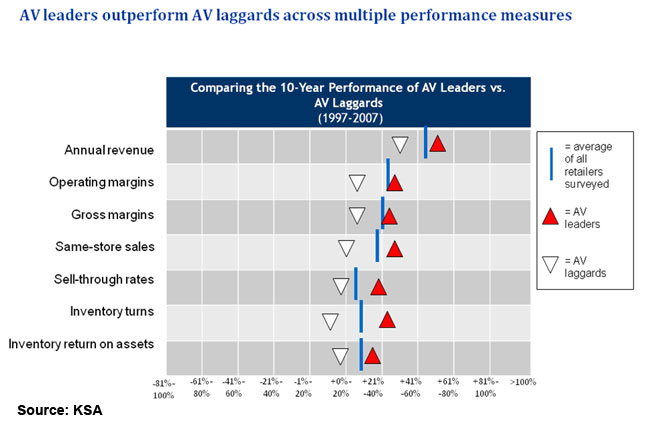

In our adaptation, Einstein’s Energy becomes our Excellence, defined by market share, margin and inventory performance. As shown below, our research has shown that companies which adopt an Act Vertical framework have performed significantly better over a 10-year period than those which do not.

Einstein’s mass becomes merchandising, combining the elements of enhanced strategic assortment planning with the engineering of memorable customer experiences to capture share.

His c2 represented the speed of light. The best retailers are making astounding improvements in the time required to bring product to market. Increased speed drives results by putting trend-fresh product on shelves, manufactured in quantities tied more closely to customer demand.

We’ll leave the m to the Merchants for today and focus on how we must evolve our logistics operations to support the increased speed (c2) that will be required of our supply chains to ensure success.

Back to “dog years” for a minute.

Fortunately, very few retailers today operate with the “No Vertical," silo-based model that was almost universal as recently as the early 1990s. VPs of Distribution have evolved into SVPs of Supply Chain and Chief Supply Chain Officers, responsible for activities which combine activities across functions to drive enhanced performance.

We find most retailers have evolved their organizations to the “Talk Vertical” stage in which, at least around the table, representatives of merchandising, product development & sourcing, logistics and store operations share in the responsibility of bringing product to market profitably. We find most retailers have evolved their organizations to the “Talk Vertical” stage in which, at least around the table, representatives of merchandising, product development & sourcing, logistics and store operations share in the responsibility of bringing product to market profitably.

While vertical thinking dialog is beginning to happen around the conference room table, there is a natural lag in the adaptation of supply chain infrastructure to enable the streamlined product movement required to deliver the benefits of Act Vertical.

Supply chain professionals at the most successful retailers are taking control and proactively working with their colleagues to retrofit infrastructure to support the more flexible product movement requirements of the Act Vertical world.

In most cases, this entails repurposing DCs originally built in the days of post-distribution processing to meet increasingly complex needs such as:

- Multi-echelon network configuration

- Cross-dock operations

- Hold & Flow capability

- Multi-channel processing

- Multi-divisional processing

This exercise can be likened to an episode of This Old House, where Norm and the gang retain the venerable façade of an historic structure while replacing the guts with state-of-the-art technology. So far, so good; these steps are relatively self-contained within the purview of the Logistics management team.

This is where the Act Vertical kicks in.

Just reconfiguring the DC will not drive the increased speed, flexibility, and reduced inventory investment required to deliver the Act Vertical vision. Enhancements must be made to upstream (merchandising, product development & sourcing) and downstream (store-level) processes and systems to enable the benefits of the turbo-charged DC network to be delivered.

This involves the whole organization analyzing three fundamental elements of supply chain strategy:

Flexibility

- Where will merchandise be coming from and what is the best path for merchandise to flow from source to store shelf?

- Do our manufacturing and packaging specs align with the concept of generating maximum speed through the logistics network?

- What configuration of owned and outsourced transportation and facility infrastructure will meet projected volume and concept growth plans while maximizing return on assets and minimizing operating expense?

Visibility & Control

- Can we see and control our merchandise ex-factory through to the store floor?

- Do our merchandising processes and systems support allocation as early as point of manufacture?

- Do transportation systems and processes track movement and provide the structure for in-transit decision making?

Execution

- Are all elements of the Act Vertical supply chain measured by the same metrics?

- Are programs in place to drive maximum efficiency from labor and assets across the supply chain?

In the past, all of these questions were simply too big and messy to be answered by one silo within the organization. As a result, we fell back to optimizing what we could control, in the process, leaving the overall supply chain ill-equipped to deliver against the Act Vertical framework. In the past, all of these questions were simply too big and messy to be answered by one silo within the organization. As a result, we fell back to optimizing what we could control, in the process, leaving the overall supply chain ill-equipped to deliver against the Act Vertical framework.

Times have changed dramatically in just 2 dog years.

We are witnessing a fortunate coalescence of several factors simply driving the retail industry to change.

Enhanced merchandising and supply chain systems are expanding in capability and growing in deployment.

Vendors are collaborating with retailers like never before to bring product to market that meets shared goals.

Solution and service providers have consolidated, expanding capabilities that enable the construction of more flexible supply chains.

And finally, we’re dealing with a customer, and in an economy which just keeps getting more and more challenging.

It’s no wonder that the most successful retailers have found a way to unify all of the parts in creating more nimble supply chain operations that deliver results.

The remaining 3 installments of this series of articles will examine in more detail the building blocks of the Act Vertical supply chain

Jack Horst is a Principal at Kurt Salmon Associates, a leading consulting and solution provider to the retail and consumer goods industries.

Agree

or disgree with our guest expert's

perspective? What would you

add? Let us know your thoughts

for publication in the SCDigest

newsletter Feedback section,

and on the web site. Upon request,

comments will be posted with

the respondent's name or company

withheld.

|