Lift Truck Management Maturity Model

Rush offered a set of distribution center maturity models across inventory, vehicle and labor management, with much of the conversation focused on the vehicle management side.

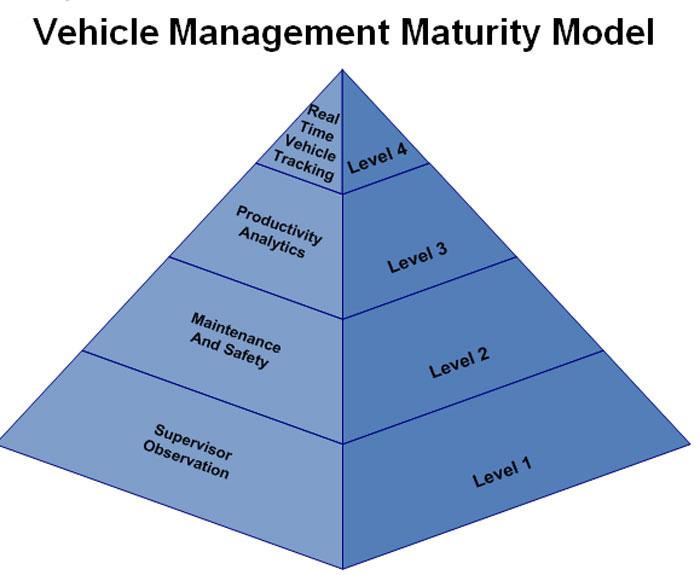

Rush sees four levels of lift truck management maturity:

Level 1: Basic supervisor observation, using manual/experienced-based approaches

Level 2: Maintenance and safety focused vehicle management, where some electronic tools are used, but they are limited in scope to the vehicles themselves, not broader DC performance

Level 3: Productivity Analytics, which use more advanced software tools to understand some of what in going on in terms of lift truck and driver efficiency, generally by looking at reports about how much time drivers spent driving, stopped, etc., and some understanding of movement paths.

Level 4: Real-time vehicle tracking, which integrates vehicle management with real-time inventory tracking.

Source: Rush Tracking

"The impact of knowing exactly where your inventory is in the DC within an inch or two can have a significant impact on lift truck productivity," Rush says. "When you add these kinds of capabilities, the traditional vehicle management capabilities come along almost for free."

Rush noted, for example, that the detailed, real-time positioning systems will offer the capability for "accident avoidance" by sending instant audio and visual signals to drivers if it appears there is a risk, for example, of two trucks colliding.

One challenge, of course, is defining the scope of the problem/opportunity to begin with. Vehicle Management System projects often do arise from the maintenance organization, and in some cases that may be the appropriate level of system and capabilities for a given organization.

However, Rush said, when such a project arises it should often be a catalyst to take a deeper look at what kinds of capabilities the distribution center really needs, and to better understand what factors - such as inventory accuracy and current handling processes - really drive lift truck performance.

What are your thoughts on Vehicle Management Systems? Do you like this maturity model? What would you add or change? Let us know your thoughts at the Feedback button below.

SCDigest is Twittering!

Follow us now at https://twitter.com/scdigest |