From Strategic to Tactical

Supply chain network optimization is a term that applies to both a process, as well as a set of focused software tools. These tools enable companies to understand options and trade-offs for different supply chain network designs and to answer the following types of questions:

- What is the optimal allocation of materials or customers to plants and/or distribution centers (DCs)?

- What is the best location for new plants and/or DCs to minimize freight, inventory holding, and/or rail fleet costs while maximizing customer service levels?

- How do we reallocate our capacity so we may close (temporarily or permanently) underperforming plants?

- What capacity should we build into our plants, production lines, or processes, down to the requirements of specific machines or tools?

- Based on our inventory levels and production capabilities, what is the optimal product mix, considering co- and byproducts?

- Based on seasonal demand or production limits, what should we pre-build in inventory?

- How do we optimize our production and distribution schedules for the desired levels of customer service and profitability?

- What is the profitability impact of crossing borders — from currency rates, tariffs, or duties?

In the past, supply chain network optimization tools were typically used to answer these types of questions and make decisions at a strategic level – with a time horizon of perhaps three years.

Now, says Manufacturing Insights, this network analysis is being used over different time horizons, which increasingly includes tactical planning over quarterly or monthly time buckets.

As a result, such insight into the supply chain network is also being used to bridge the gap between production and demand as a precursor to more detailed planning as part of the Sales and Operations Planning process.

While all supply chains have a set of network trade-offs to manage, what makes these processes and decisions different for asset-intensive supply chains is basic and revolves around the imperative to drive improved return on assets and asset utilization.

The global recession and incredible market dynamics are making the need for such network optimization in both the strategic and tactical sense more important than ever.

“As companies have been forced to re-look at their business models due to declining sales and/or profits, the supply network is an obvious candidate for transformation,” Knickle and Ellis write. “Having sophisticated tools may well make the difference between riding out the economic downturn and becoming a victim of it.”

They note that the focus of such network analysis is quite different depending on the demand-supply balance. When capacity is tight, attention is generally on logistics aspects of the supply chain to maximize the flow of goods to customers. When demand exceeds supply, the focus is on reducing capacity to improve asset utilization and per unit operating cost.

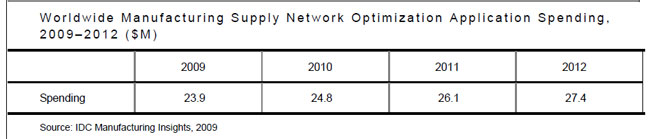

Manufacturing Insights expects growth of spending on supply chain network design tools to be in the mid-20% range over the next five years – an impressive growth rate that supports the likelihood that asset-oriented companies and others will be using these tools to both redesign networks and make more tactical planning decisions with increasing frequency.

SCDigest is Twittering!

Follow us now at https://twitter.com/scdigest

|