| |

|

| |

|

|

Supply

Chain by the Numbers |

| |

|

| |

- Oct. 19, 2017 -

|

| |

|

| |

|

| |

|

| |

Amazon Locking Up Aparment Delivery Systems; Truckers becoming Over the Road Gourmets with Improve Cooking Tools; Are You Ready for the Plastics Free Grocery Aisle? Fanuc Using Cloud-Based AI to Improve Factory Robot Performance |

| |

|

| |

| |

| |

850,000 |

|

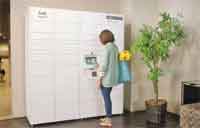

| That is how many apartment units in the US for which Amazon has already contracted to install delivery lockers on the property in deals with the controlling real estate companies. Amazon has been rolling out the locker concept for several years now, often in partnership with retailers such as 7-11 convenience stores and Staples, and recently announcing it would be adding lockers at its newly acquired Whole Foods units. The secure lockers allow delivery persons to stow Amazon orders for customer pick-up using a smart phone app to receive a code. Customers do the same to retrieve the goods. The system allows orders to be secured until pick-up, and often provides more flexible options for retrieving the orders in terms of time. The program for apartments, which the retailer is calling Hub by Amazon, may provide the additional benefit to apartment managers by reducing the growing and almost overwhelming burden of dealing with perhaps hundreds of packages from on-line orders showing up every day. Importantly, Amazon says the lockers will support deliveries from other companies, not just for orders placed by its customers. Amazon will charge $10,000 to $20,000 to purchase the lockers initially, the Wall Street Journal reports, but then apartment owners will not have to pay a monthly fee. This will give Amazon some level of control of "last mile" deliveries, and that 850,000 units committed to the system is likely to grow substantially. |

|

|

| |

| |

|

|

|

That is the success rate of picking individual parts out of a bin that a robot from Japan's Fanuc Automation can now achieve after 5000 attempts – up from 60% after 1000 tries. And the number will go higher. Why? As you probably suspect, Fanuc is employing machine learning technology, in which the robot software teaches itself about what is working and what is not, rather than having programmers and engineers keep improving the software to get better results. Instead, the improvement came "without a single line of program code having to be written," a statement from Fanuc recently said, as quoted in a fascinating article this week in Bloomberg. Fanuc, in fact, is investing heavily in artificial intelligence, hoping to be for AI on the factory floor what Google is for internet search. That includes a new Cloud-based platform that "allows Fanuc to collect global manufacturing data in real time on a previously unimaginable scale and funnel it to self-teaching robots," Bloomberg says. The implication is that learnings from one robot could be applied to other robots across the globe. Wow. In Fanuc's multiple factories, robots make the robots. Where all this is headed is a key societal question. |

| |

| |

|

| |

| |

23% |

|

That is the percent of US plastic water bottles that are recycled, according to the Banthebottle.com web site. In the UK, the figure is a somewhat higher 29%. But that doesn't even really matter much, according to recent comments by Andy Clarke, who spent six years as CEO of Asda, the Walmart-owned grocery chain that is the third largest in the UK. That's because plastic doesn't recycle very well, Clarke says. "Unlike materials like aluminum and glass, plastic packaging cannot be recycled ad infinitum," Clarke noted, adding that "Most items of plastic packaging can only be recycled twice before they become unusable. Recycling will never offer a durable solution to the plastic crisis - we simply have to use less plastic in the first place." In fact, Clarke is calling on grocers to develop "plastics free aisles" in their stores, using more recyclable materials and new age packaging material such as grass paper. Much plastic packaging makes its way into oceans and other waterways, and some is ingested by people eating fish Clarke says, also warning plastic can leave a cancer-causing residue on some foods. Clarke is supported in his efforts by a Green organization called Plastic Planet whose whole mission is about pushing for creation of plastic free aisles in stores. But the movement seems much stronger in the UK than in the US.

|

| |

| |

|

|

|

| |

|

|

| |

|

|

| |