The relationship between engineering/product design and the supply chain has always been a somewhat sketchy one, as frankly the two areas have tended to operate in relative silos in many companies.

That has started to change, certainly in areas such as including new product introduction planning into the S&OP process, design for manufacturing, and a more general focus on internal collaboration, often by use of shared executive metrics.

Dr. David Simchi-Levi of MIT has been well articulating lately how much decisions in product design (for example, how modular a product's manufacturing is or isn't) directly impact the degree of supply chain flexibility the company will have, a subject that not that many years ago was not really often considered in product design.

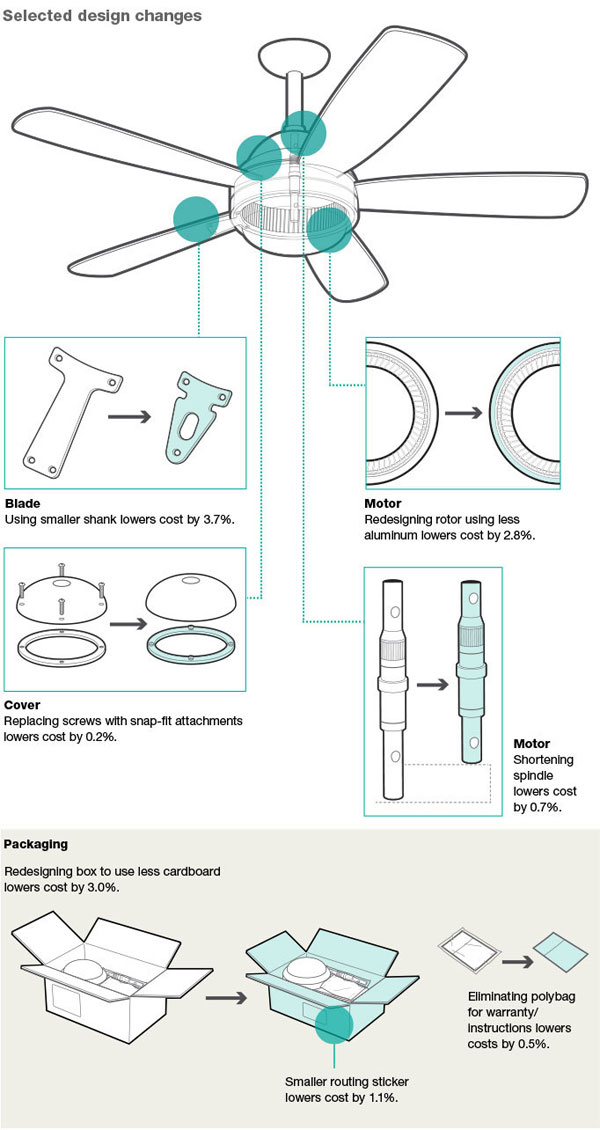

All that as a lead in to the graphic below, from the McKinsey Quarterly. That article, on "designing products for value," says that globalization in terms of markets and competitors means companies must get smarter than ever in product design, especially weeding out design elements that don't really add custom value.

An home durables company with a somewhat struggling line of ceiling fans recently went through an exercise that included some deep consumer research, along with a fresh look at its fan designs.

As McKinsey notes: "Purchasers and product engineers believed that it was

already striking the right balance between quality and price in its

materials and components. Yet the teardown [of competitors' products] showed that as compared with

competitors, the company was "overbuilding" its products significantly

and that identical—or even better—product performance was possible at a

lower cost if the team was willing to rethink its design approaches."

The cost savings opportunities in sourcing and manufacturing are nicely illustrated below.

Value Engineering in Ceiling Fans

In total, product costs from the exercise were lowered by more than 10%.

Are there simialr opportunities in your supply chain?

McKinsey says it really takes a team effort across engineering, marketing and the supply chain, because the cost savings opportunities can only be correctly identified if they are connected to what customers will or won't pay for, and how they can impact overall supply chain costs.

Any Feedback on our Supply Chain Graphic of the Week? Let us know your thoughts at the Feedback button below.

|