We all know that supply chain network complexity is growing, driven by globalization, SKU proliferation, multi-channel strategies, and moire.

That in turn puts even more pressure on inventory management in the face of that froqing network complexity.

Additionally, companies increasing realize that managing inventories "one node at a time," rather than holistically, is never going to lead to top-level inventory performance. Hence the interest in such tools as "inventory optimization" software, and improved visibility, to deal with multi-tier inventory management.

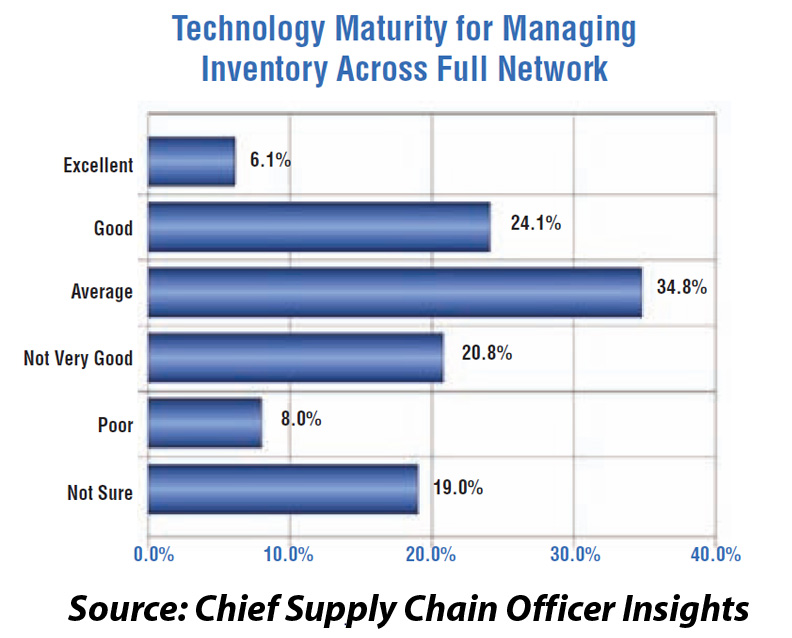

CSCO Insights tackled all these issues and more in a recent Supply Chain Executive Brief titled Five Strategies for Reducing Supply Chain Network Inventories. Taken from that report is the graphic below, in which 250 respondents answered a question about how good the state of their current technolgy is to manage the challenges of netwrok inventory management.

As can be seen, just 6.1% thought their current technology as Excellent for managing network inventories holistically. Conversely, 63.6% viewed their current capabilities as eith Average, Not Very Good, or Poor.

This and a whole lot more is in the full report, available here:

Supply Chain Executive Brief: Five Strategies for Reducing Supply Chain Network Inventories.

|