Have we entered the Optimization 3.0 era?

That was the premise of a recent Supply Chain Videcast featuring Thomas Dong of IBM, who said tremendous advances in computing power are leading to significant new opportunities to leverage optimization technology in the supply chain. To see the excellent full videocast on demand, go here: Optimization 3.0 Videocast.

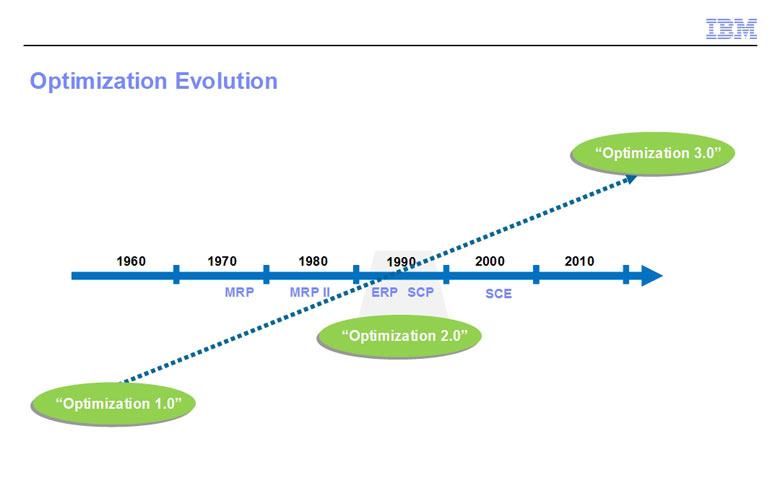

Dong said the first phase of optimization began in the late 1940s, when George Dantzig invented the Simplex method, the foundation of Linear Programming (LP) and more generally the discipline of mathematical optimization. Optimization provides a scientific means to determine the best decision across a set of constrained resources. The technology was first used in applications such as airline "yield management" and optimizing telecommunications networks and routing.

Optimization 2.0 was seen during the 1990s and beyond, as optimization tools were deployed to solve supply chain problems, such as supply chain network design and transportation planning. Optimization technology was used either as standalone tool sets companies themselves would adopt, or leveraged as embedded components in commercial software packages.

Source: IBM

Optimization 3.0 is happening now, Dong says, and is made possible by the huge advances in computing power. How much has it changed? Dong says that several years ago, increased computer horse power plus improved algorithms in the solvers had improved optimization performance more than 5 million times versus older technology. More advances have occurred since then.

Why is this important? Because it allows companies to now use optimization technology to solve problems that simply weren't feasible before, given the time it took to run the solvers. This greater perofrmance will also allow creation of "real-time analytics" for both decision support and automated action. This indeed is what Dong says is the future of supply chain technology.

Case in point: An IBM semiconductor factory that reschedules itself every 5 minutes across numerous processes and variables, a scheduling frequency simply unimaginable with even second generation optimization technology.

This is where we are headed.

Agree or

disagree? What is your perspective? Let

us know your thoughts at the Feedback button

below

|